Top Benefits of Super Finishing Process for Precision Engineering Applications

In the realm of precision engineering, the demand for superior surface quality and enhanced performance characteristics is more critical than ever. As industries such as aerospace, automotive, and medical devices strive for higher precision and reliability in their components, the implementation of innovative finishing techniques has become essential. Among these techniques, the "super finishing process" stands out due to its ability to achieve micro-level surface finishes that significantly reduce friction and wear, thereby enhancing the longevity and efficiency of mechanical parts.

According to a report by MarketsandMarkets, the global precision engineering market is projected to reach USD 1,500 billion by 2025, driven by an increasing focus on quality and performance. As a key contributor to this market, the super finishing process helps manufacturers meet stringent quality standards while also supporting advancements in technology, such as the miniaturization of components and the integration of smart technologies. The ability to refine surfaces to sub-micron levels not only boosts the aesthetic appeal of products but also plays a vital role in reducing operational costs through improved energy efficiency and reduced maintenance needs.

As the landscape of precision engineering evolves, embracing the super finishing process can provide manufacturers with a competitive edge, enabling them to deliver high-quality products that meet the demands of modern applications while adhering to rigorous industry standards.

Overview of Super Finishing Process in Precision Engineering

The super finishing process is a highly specialized technique employed in precision engineering, particularly for enhancing the surface quality of manufactured components. This process involves removing only a small amount of material, typically in the micrometer range, which leads to significantly improved surface finish and dimensional accuracy. Research indicates that super finishing can achieve a surface roughness of as little as Ra 0.01 to Ra 0.025 micrometers, which is essential for parts used in high-performance applications such as aerospace, automotive, and medical devices. According to a recent study by a leading engineering journal, components subjected to super finishing exhibit less wear and a higher fatigue strength, leading to extended service life and reduced failure rates.

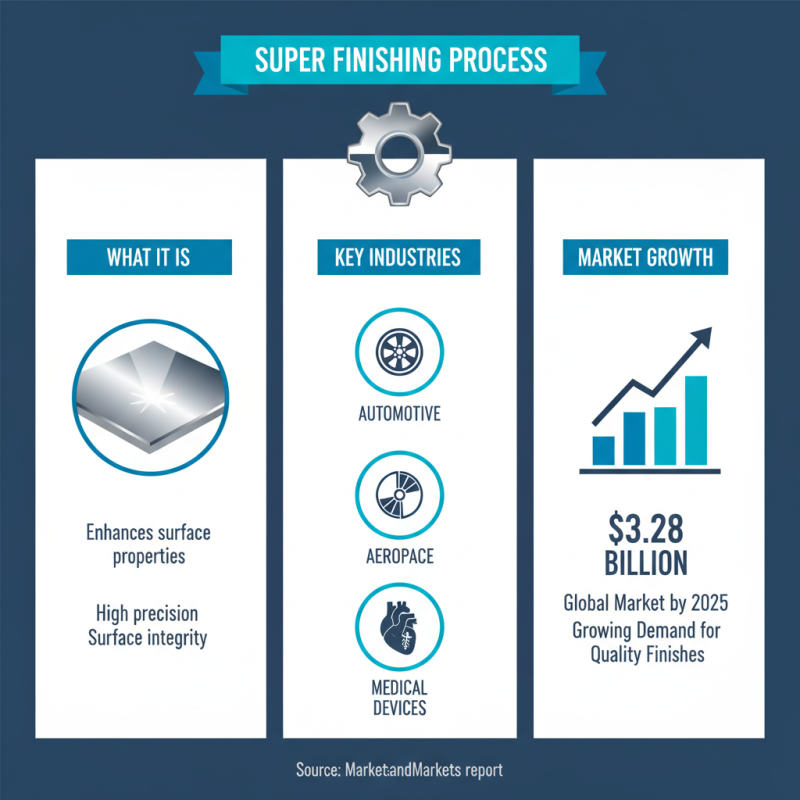

In precision engineering, the adoption of super finishing techniques has grown in response to the increasing demands for tighter tolerances and enhanced material properties. Data from industry reports reveal that the global super finishing market is projected to grow at a CAGR of over 5% through 2025, underscoring its significance in modern manufacturing. This growth is driven by the rise in automated processes and advanced materials, which necessitate superior finishing techniques to meet stringent performance standards. The ability of super finishing to eliminate micro-imperfections while supporting the integrity of parts positions it as a critical step in the manufacturing workflow, contributing to overall quality assurance in precision-engineered products.

Key Advantages of Super Finishing for Surface Quality Improvement

The super finishing process is a pivotal technique in precision engineering, particularly renowned for its ability to enhance surface quality significantly. This advanced finishing method utilizes abrasive methods such as polishing, lapping, and micro-polishing to achieve ultra-smooth surfaces. One of the key advantages of super finishing lies in its capability to minimize surface roughness. By reducing imperfections on components, this process not only enhances aesthetic appeal but also improves functional performance, which is crucial in applications requiring tight tolerances and high reliability.

Moreover, super finishing contributes to increased durability and reduced friction in mechanical components. By creating a highly refined surface, the process decreases wear and tear when parts interact, leading to longer lifespan and lower maintenance costs. Additionally, improved surface quality directly influences fluid dynamics; smoother surfaces can enhance lubrication retention and reduce energy losses in moving parts. This aspect is especially beneficial in industries such as automotive and aerospace, where efficiency and performance are paramount. Overall, the enhancement of surface quality through super finishing plays a vital role in optimizing the reliability and functionality of precision-engineered components.

Impact of Super Finishing on Dimensional Accuracy and Tolerance

The super finishing process is a critical technique in precision engineering, primarily aimed at enhancing dimensional accuracy and tolerance in engineered components. During this process, surface irregularities are minimized to achieve exceptionally smooth finishes, which are essential for components that require high precision. The removal of micro-scale defects not only improves the surface texture but also significantly contributes to the overall dimensional stability of the parts. This enhancement directly impacts the fit and function of mechanical assemblies, leading to improved performance and longevity.

Moreover, the influence of super finishing on tolerance control cannot be overstated. Tolerances are pivotal in determining how well parts assemble and perform in their respective applications. By using super finishing techniques, manufacturers can achieve tighter tolerances that meet or exceed industry standards. This process allows for more precise control over geometrical parameters, resulting in components that are dimensionally consistent and reliable. The high level of craftsmanship ensures that deviations in size and shape are kept to a minimum, thus facilitating better interoperability of parts within complex mechanisms. Ultimately, the super finishing process emerges as an indispensable method for ensuring that precision engineering applications meet rigorous demands for accuracy and reliability.

Top Benefits of Super Finishing Process for Precision Engineering Applications

| Benefit | Description | Impact on Dimensional Accuracy | Impact on Tolerance |

|---|---|---|---|

| Improved Surface Finish | Achieves a smoother surface than traditional methods, reducing friction. | Enhances dimensional stability and reduces wear. | Allows for tighter tolerances by minimizing surface irregularities. |

| Enhanced Dimensional Control | Provides precise control over the dimensions of the parts. | Maintains tighter tolerances throughout the manufacturing process. | Improves the ability to meet strict tolerance requirements. |

| Reduced Friction | Minimizes surface roughness, leading to lower friction between components. | Improves operational accuracy under dynamic conditions. | Allows for higher tolerances by reducing mechanical play. |

| Increased Component Longevity | Enhances durability by reducing wear and tear on components. | Contributes to maintaining dimensional integrity over time. | Ensures that parts remain within specified tolerances longer. |

Materials Suited for Super Finishing in Precision Applications

The super finishing process plays a crucial role in enhancing the surface quality of various materials in precision engineering applications. This technique is particularly effective for metals such as steel and aluminum, which are widely used in industries including automotive and aerospace. According to a recent industry report by the International Journal of Precision Engineering, components treated with super finishing can exhibit a surface finish improvement of up to 90%, significantly reducing friction and wear, which is crucial for extending the lifespan and performance of precision parts.

In addition to metals, super finishing can also be applied to composite materials, ceramics, and even polymers. As noted in a 2022 market analysis by the Society for Manufacturing Engineers, an increasing demand for high-performance materials in precision engineering has led to a rise in super finishing applications for these non-metallic substrates. Components like gears, bearings, and valve seats benefit from improved surface integrity, leading to enhanced mechanical properties and reliability in demanding environments. The choice of materials subjected to super finishing, such as high-performance alloys and engineered plastics, underlines the versatility of this process in meeting the stringent requirements of modern engineering applications.

Top Benefits of Super Finishing Process for Precision Engineering Applications

Applications and Industries Benefiting from Super Finishing Techniques

The super finishing process is increasingly valuable in precision engineering applications across various industries, enhancing the properties of manufactured components. This process is utilized in sectors such as automotive, aerospace, and medical devices, where high precision and surface integrity are critical. According to a report by MarketsandMarkets, the global super finishing market is projected to reach $3.28 billion by 2025, showcasing its growing importance amidst rising demands for high-quality surface finishes.

In the automotive industry, super finishing techniques improve gear and bearing surfaces, contributing to reduced friction and wear. This not only extends the lifespan of components but also improves fuel efficiency. Additionally, in the aerospace sector, where every gram matters, the consistent precision achieved through super finishing can significantly contribute to weight reduction and overall aircraft performance. The medical field also benefits, as super finishing enhances the biocompatibility of implants, ensuring a smoother surface that supports better integration with human tissues.

**Tip:** When considering super finishing for your engineering projects, it’s crucial to assess the specific requirements of the application, such as desired surface roughness and the type of material involved. Collaborating with experts in super finishing can lead to optimized solutions tailored to your engineering challenges. Another tip is to conduct thorough quality checks post-finishing to ensure that the surface properties meet the industry standards.

Related Posts

-

Revolutionizing Manufacturing: The Impact of Super Finishing Process on Product Quality and Efficiency

-

How to Choose the Right Ejector Pins for Your Injection Molding Projects

-

How to Choose the Right Bevel Gears for Your Precision Engineering Needs

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future