2026 Best Plastic Injection Techniques for Efficient Manufacturing?

In the fast-evolving world of plastic injection, efficiency is key. Industry expert Dr. Emily Carter once stated, "The future of plastic injection lies in innovative techniques." Her insight reflects the ongoing quest for better methods in manufacturing.

Plastic injection is not just about speed. It involves precision and quality control. With advancements in technology and materials, manufacturers face both opportunities and challenges. It's vital to adapt to new techniques while maintaining product integrity.

As we delve into the best plastic injection techniques of 2026, we must also consider the environmental impact. Sustainable practices are increasingly necessary. Companies often grapple with balancing efficiency and ecological responsibility. This ongoing reflection shapes the future of plastic injection manufacturing.

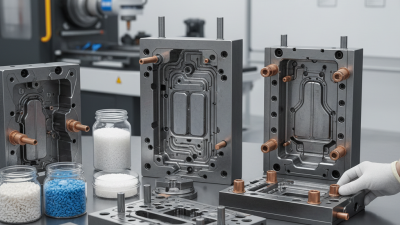

Overview of Plastic Injection Molding Techniques in 2026

In 2026, plastic injection molding continues to evolve, driven by innovations in technology and materials. According to industry reports, more than 30% of manufacturers are adopting advanced robotics in their injection processes. This integration enhances precision and reduces cycle times. Robots can handle repetitive tasks efficiently, decreasing the risk of human error during production.

However, challenges remain. Many companies struggle with the high costs of implementing these technologies. A report by the Society of Plastics Engineers noted that 20% of firms have delayed upgrades due to budget constraints. Additionally, sustainability is a growing concern. While recycled materials are increasingly used, their quality often varies, leading to inconsistent product performance. This inconsistency can disrupt supply chains and impact overall production efficiency.

The need for skilled workers is another pressing issue. As techniques become more advanced, firms may find it difficult to retain experienced personnel. A recent survey indicated that 40% of production managers feel unprepared for new technology demands. Addressing these skills gaps is crucial for maintaining competitive advantage in the fast-paced manufacturing landscape.

2026 Plastic Injection Techniques Efficiency Comparison

This chart presents an overview of various plastic injection molding techniques and their estimated efficiency in manufacturing for the year 2026. The efficiency is measured based on factors like cycle time, cost-effectiveness, and material utilization.

Advancements in Material Science for Enhanced Injection Efficiency

Advancements in material science have transformed the realm of plastic injection molding, enhancing efficiency and sustainability. Innovations such as bio-based plastics offer a reduction in carbon footprint, with reports indicating up to 30% lower greenhouse gas emissions compared to traditional materials. New formulations also play a vital role. For example, incorporating additives can improve flow rates, leading to shorter cycle times and reduced energy consumption. The latest studies suggest that optimizing material properties can yield up to a 15% increase in production rates.

Tip: When selecting materials, consider performance metrics such as viscosity and thermal stability for optimal results.

Another noteworthy development in this field is the use of advanced mold designs. Recent research highlights that implementing conformal cooling channels can reduce cooling time by 25%. This reduction directly impacts cycle time and productivity, making a great difference in large-scale operations. Yet, the integration of new technologies can present challenges. Engineers must embrace trial and error to find the right balance between innovation and existing processes.

Tip: Regularly evaluate your mold design to ensure it meets evolving production needs.

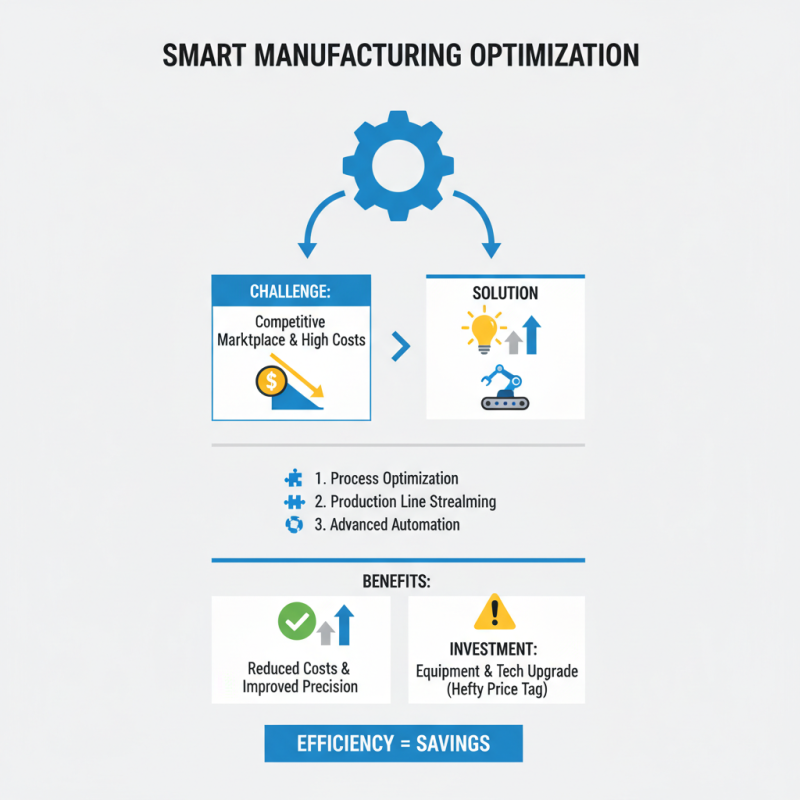

Innovative Process Optimizations for Cost-Effective Production

In today's competitive marketplace, efficient manufacturing is more critical than ever. Many companies are now focusing on innovative process optimizations to reduce costs. Streamlining production lines can result in significant savings. Adopting advanced technologies like automation can improve precision. However, investing in new equipment often has a hefty price tag.

One area often overlooked is employee training. Well-trained staff can operate machinery more efficiently, minimizing errors. A focus on workforce skill development is essential. It's not just about machines; it’s about people. Innovation sometimes leads to glitches. Identifying and correcting these issues require time and patience.

Another thought is the raw materials used in production. Sourcing lower-cost materials may seem enticing, but this can affect product quality. Balancing cost and quality remains a challenge for many manufacturers. Regular reviews of production processes help pinpoint inefficiencies. Staying ahead means embracing both successes and mistakes in the journey toward optimal manufacturing.

Sustainable Practices in Plastic Injection Manufacturing

Sustainable practices in plastic injection manufacturing are essential for reducing environmental impact. The global production of plastic is expected to reach 1.1 billion metric tons by 2030, according to various industry reports. This surge raises pressing concerns about waste and pollution. A focus on sustainability can help mitigate these issues.

One emerging technique is the use of biodegradable materials combined with traditional plastics. Reports suggest that using materials like PLA or PHA can reduce reliance on petroleum-based products. Furthermore, advances in recycling methods are crucial. Approximately 80% of plastic waste is not recycled, indicating a need for improved recycling technologies. The integration of post-consumer recycled (PCR) materials into new products can significantly lower carbon footprints.

Implementing energy-efficient machines is another important factor. Existing data show that energy consumption during production can be reduced by up to 30% with the right equipment. However, many manufacturers still overlook this option. There are also challenges in securing sustainable suppliers, which can complicate efforts for greener processes. Balancing cost and sustainability remains a complex issue in the industry.

Future Trends: Automation and Smart Technologies in Injection Molding

The landscape of injection molding is rapidly evolving. Automation and smart technologies are reshaping how manufacturers operate. Industry reports suggest that 70% of injection molding companies plan to invest in automation by 2026. This shift aims to reduce cycle times and improve precision. Yet, these advancements can also create challenges. Many companies struggle with the initial costs and training for skilled technicians.

Smart technologies like IoT sensors are becoming common in production lines. These sensors provide real-time data on machine performance and product quality. For example, predictive maintenance systems can reduce downtime by 30%. However, integrating these technologies requires a cultural shift within organizations. Employees might resist changes, fearing job losses or demanding additional training. It's essential to address these concerns to create a more effective, tech-driven workplace.

While these advancements promise efficiency, problems often arise. Implementation can be complex and costly. There might be a learning curve for staff. Human oversight is still needed to ensure quality. Balancing technology with the human touch remains crucial. The future of injection molding lies in overcoming these hurdles. Adopting automation and smart technologies is only one part of the journey.

Related Posts

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners

-

The Best 10 Plastic Mold Techniques You Should Know?

-

How to Choose the Right Plastic Injection Tooling for Your Project?

-

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing