What is Bevel Gears and How Do They Work?

Bevel gears are critical components in many mechanical systems. They enable the smooth transfer of power between shafts that meet at angles. According to Dr. Emily Hart, a leading expert in mechanical engineering, “Bevel gears are vital for changing the direction of power transmission.”

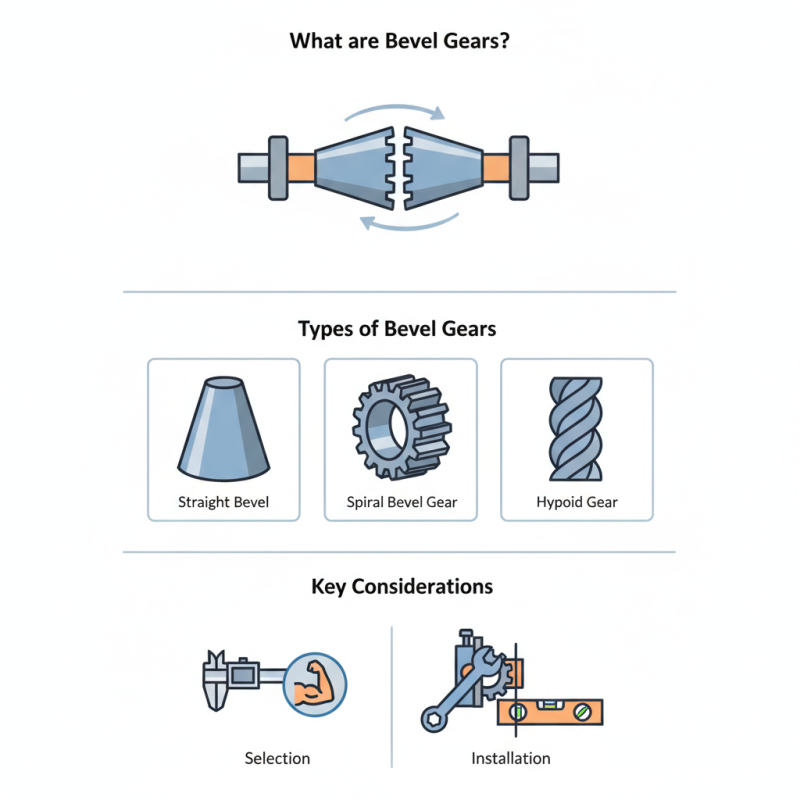

They come in various shapes, including straight, spiral, and hypoid gears. Each type has unique properties that make it suitable for different applications. However, selecting the right bevel gear can be challenging. Miscalculations in size or material can lead to inefficiency.

Furthermore, the installation process requires precision. A poor alignment can cause premature wear and failure. Understanding bevel gears is essential for those involved in mechanical design and maintenance. Their proper use can greatly enhance the performance of machinery.

What Are Bevel Gears: Definition and Types

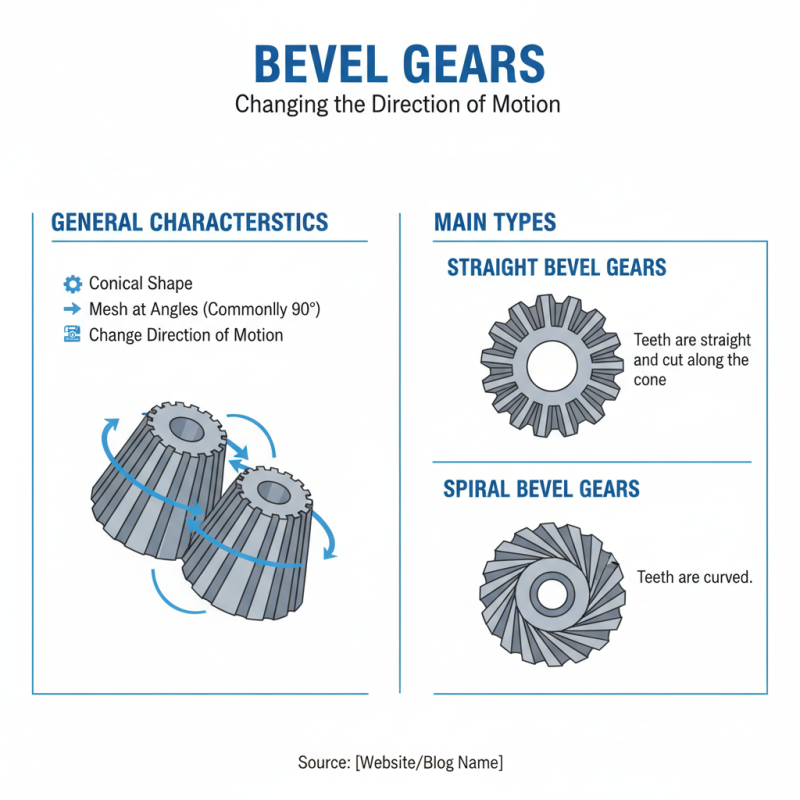

Bevel gears are unique mechanical components that help change the direction of motion in various machines. These gears typically have conical shapes, allowing them to mesh at distinct angles, commonly at 90 degrees. There are mainly two types: straight bevel gears and spiral bevel gears. Straight bevel gears have teeth that are straight and cut along the conical surface. In contrast, spiral bevel gears possess teeth that are curved. This difference impacts how they interact and function.

In practical applications, bevel gears are widely used in tools and automotive systems. They efficiently transmit power while changing the rotation direction. The design choice can affect performance. For example, straight bevel gears might create more noise compared to their spiral counterparts. Yet, they can be easier to manufacture. Choosing between them can be a challenge. Performance, cost, and space constraints must all be considered. Each type has advantages and disadvantages, making it essential to assess your specific needs carefully. Bevel gears play a crucial role in many devices, but understanding their nuances is vital for optimal use.

Key Applications of Bevel Gears in Various Industries

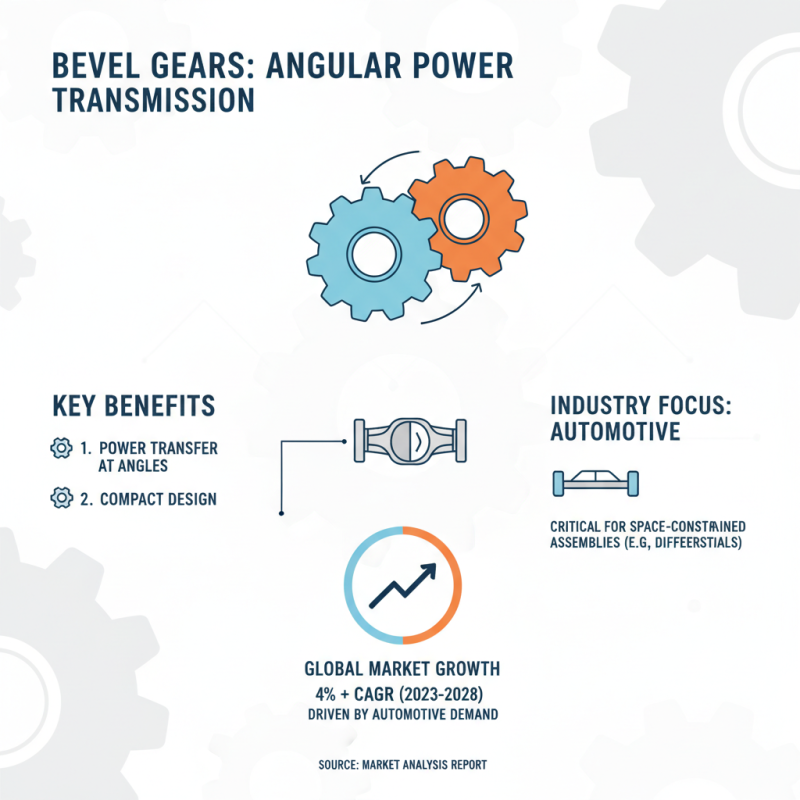

Bevel gears play a crucial role across various industries. Their unique design allows for the transmission of power between shafts at different angles. This characteristic is particularly beneficial in automotive assemblies, where space is tight and angles are critical. According to a recent market analysis, the global bevel gear market is expected to grow by over 4% each year, driven by rising demand in automotive manufacturing.

In the aerospace sector, bevel gears are essential for adjusting flight control systems and enhancing performance. A report highlighted that over 30% of aerospace companies focus on gear optimization for improved efficiency. Despite their advantages, some manufacturers struggle with precision in production. This challenge can lead to higher failure rates, costing companies both time and money in the long run.

In addition to automotive and aerospace, the wind energy sector utilizes bevel gears for turbine operations. These gears help convert the rotational energy from wind into usable electrical energy. A study suggested that optimizing gear systems could increase energy efficiency by 15%. However, implementing these enhancements requires ongoing investment and innovation, underscoring the need for constant improvement.

Understanding the Gear Ratio and Its Impact on Performance

Bevel gears are crucial components in many machinery. Understanding gear ratios helps in optimizing performance. A gear ratio indicates the relationship between the input and output speeds. This can directly affect the efficiency of a system. For instance, a higher gear ratio often leads to increased torque, but may lower speed. Conversely, a lower ratio provides high-speed output at the cost of torque.

Recent industry reports show that the correct gear ratio can lead to performance improvements of up to 30% in some applications. This statistic reveals the importance of selecting the right configuration. It’s essential to analyze the specific needs of each operation. Misjudging the gear ratio can lead to issues, like overheating or excessive wear.

An improperly calculated ratio can compromise performance. It may hinder machinery operations significantly. Engineers often overlook these details. Precision in selecting gear ratios, though tedious, can prevent costly errors. When gear selection is right, production runs smoothly. When it is wrong, consequences can be profound. Striving for the perfect gear ratio often requires more than calculations; it demands real-world testing.

Performance Analysis of Bevel Gears

How Bevel Gears Help in Achieving Efficient Torque Transmission

Bevel gears are essential in various machinery, playing a critical role in torque transmission. They operate by connecting shafts at an angle, often 90 degrees. This design allows for efficient energy transfer between perpendicular shafts. Proper engagement of the gears is crucial. Misalignment can lead to inefficiencies and wear.

When using bevel gears, locate them accurately. Precision in installation minimizes friction and enhances performance. It’s easy to overlook this step, but a small error can cause longer-term issues. Regular maintenance can also prevent failures. Inspecting teeth for wear can help ensure effective operation.

Tips: Always maintain proper lubrication. This reduces friction and heat, extending gear life. Monitor for unusual noises during operation; they can signal potential problems. Being proactive in gear maintenance pays off in longevity and efficiency.

Factors Affecting the Longevity and Maintenance of Bevel Gears

Bevel gears are key components in machinery, allowing for smooth changes in direction of motion. To ensure their longevity, several factors come into play. The design and materials used directly influence durability. Harder materials tend to resist wear but can increase costs. Hence, a balance needs to be struck.

Proper alignment is essential for bevel gears. Misalignment can lead to excessive wear. Regular inspections are necessary to catch problems early. Lubrication also plays a critical role. The right lubricant reduces friction and heat buildup. However, over-lubricating can attract dirt, which may cause issues.

Operating conditions matter too. Excessive loads can shorten the life of gears. If a machine operates in a harsh environment, protective covers might be needed. It requires a constant evaluation of performance. Ignoring these aspects can lead to premature failures. Sometimes, even minor adjustments can make a significant difference.

What is Bevel Gears and How Do They Work? - Factors Affecting the Longevity and Maintenance of Bevel Gears

| Factor | Description | Impact on Longevity | Maintenance Tips |

|---|---|---|---|

| Material Quality | The type of material used for manufacturing bevel gears affects wear resistance. | High-quality materials increase longevity. | Use materials with high hardness and wear resistance. |

| Lubrication | Proper lubrication reduces friction and wear between gear teeth. | Inadequate lubrication leads to premature failure. | Regularly check and refill lubricant levels. |

| Alignment | Accurate alignment ensures efficient power transmission. | Misalignment can cause excessive wear. | Inspect and adjust alignment during maintenance. |

| Load Capacity | The amount of load applied to the gears impacts their lifespan. | Exceeding load limits can result in failure. | Know the load limits and avoid overloading gears. |

| Operating Environment | Dust, moisture, and temperature can affect gear performance. | Harsh environments can shorten lifespan. | Protect gears from environmental factors. |

Related Posts

-

How to Choose the Right Bevel Gears for Your Precision Engineering Needs

-

Why Choose Bevel Gears for Your Mechanical Applications?

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

Top Benefits of Injection Molded Parts for Efficient Manufacturing Solutions?

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025