How to Choose the Right Bevel Gears for Your Precision Engineering Needs

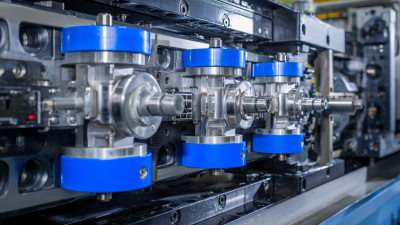

In the realm of precision engineering, the selection of appropriate components plays a crucial role in the overall performance and reliability of machinery. Among these components, bevel gears are instrumental in enabling the efficient transfer of power between shafts that are oriented at an angle to one another. According to a recent market research report by Research and Markets, the global bevel gears market is projected to grow at a CAGR of 5.4% from 2021 to 2026, indicating a significant upward trend in the demand for high-quality bevel gears across various industries, including automotive, aerospace, and manufacturing.

The critical attributes of bevel gears, such as their load capacity, efficiency, and durability, make them a vital consideration for engineers tasked with product design. The ability to choose the right bevel gears can significantly influence the operational efficiency and lifespan of machinery. With advancements in manufacturing technologies, including the rise of custom gear solutions, precision engineers must be equipped with the knowledge to assess and select bevel gears that best meet their specific application requirements. By understanding the various factors influencing gear performance—such as material selection, gear geometry, and surface finish—engineers can optimize their designs for superior operational results.

As businesses increasingly focus on enhancing productivity and reducing costs, the significance of selecting the right bevel gears cannot be overstated. This guide aims to provide essential insights and practical considerations that will aid precision engineers in making informed decisions when choosing bevel gears to fulfill their engineering needs.

Understanding the Importance of Bevel Gears in Precision Engineering

Bevel gears are essential components in precision engineering, facilitating smooth transitions between shafts that operate at varying angles, typically 90 degrees. Their significance is highlighted in a report by Market Research Future, which predicts that the global bevel gear market will grow at a CAGR of 5.9% from 2021 to 2027. This trend underscores the increasing reliance on robust bevel gear systems in high-precision applications, ranging from aerospace to robotics.

When selecting bevel gears, it's crucial to consider factors such as the material, tooth design, and load capacity. For instance, hardened steel gears can withstand higher loads, making them suitable for demanding environments. One important tip for ensuring optimal performance is to assess the gear's pitch angle and tooth count, as these will directly affect torque transmission and efficiency.

Another consideration is lubrication; keeping bevel gears properly lubricated can extend their lifespan and maintain operational efficiency. According to Gear Technology, proper maintenance can increase gear life by 50%. Therefore, investing time in understanding the specifications and maintenance needs of bevel gears is key to achieving superior performance in precision engineering projects.

Identifying Key Factors for Selecting Bevel Gears

When selecting bevel gears for precision engineering applications, several key factors must be considered to ensure optimal performance and longevity. One of the primary considerations is the gear material, as it plays a crucial role in the overall durability and efficiency of the gear system. According to a report by the Gear Research Institute, using high-quality alloys can enhance the wear resistance and load-carrying capacity of bevel gears, leading to increased operational lifespan by up to 20% compared to standard materials.

Another essential factor is the gear design and geometry. The tooth profile and the angle of the gears can significantly impact the gear's efficiency. Recent studies indicate that using computer-aided design (CAD) tools to simulate gear interactions can improve manufacturing accuracy and reduce noise levels by 15% during operation. Furthermore, precise alignment during installation is vital, as misalignment can lead to accelerated wear and failure. Consistent monitoring of operational parameters can help maintain the alignment and ensure the gears function at peak efficiency, ultimately reducing maintenance costs by approximately 10% annually.

Exploring Different Types of Bevel Gears and Their Applications

Bevel gears are essential components in precision engineering, providing efficient angular motion transmission between shafts. Several types of bevel gears are available, each with unique characteristics suited for specific applications. The most common types are straight bevel gears, spiral bevel gears, and hypoid gears.

Straight bevel gears feature straight teeth and are ideal for applications requiring simpler, cost-effective solutions, such as in basic machinery and automotive differentials. Their straightforward design, however, may lead to higher noise levels and less smooth operation compared to other types.

Spiral bevel gears, on the other hand, are designed with teeth that are curved, allowing for smoother engagement and higher load capacity. This makes them particularly suitable for applications in high-speed machinery and heavy-duty equipment, where efficiency and noise reduction are critical.

Hypoid gears, a specialized version of spiral bevel gears, allow for non-intersecting shafts, providing greater versatility in design and application. They are commonly found in automotive drivetrains and industrial machinery, where space and angle constraints are significant.

Understanding these differences is crucial for engineers when selecting the appropriate bevel gear type for their specific precision engineering requirements.

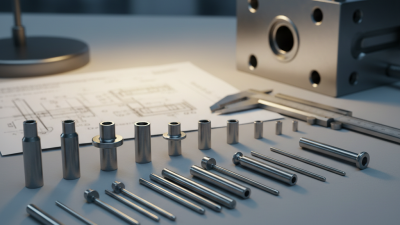

Evaluating Material and Manufacturing Methods for Bevel Gears

When selecting bevel gears for precision engineering applications, evaluating the material and manufacturing methods is crucial. Recent advancements in heat treatment control technologies demonstrate how critical it is to optimize treatment parameters for high-strength steel gears. Research shows that improper selection of heat treatment parameters can lead to suboptimal gear performance, impacting the overall reliability of mechanical systems. Innovative approaches, such as employing support vector machines in controlling heat treatment processes, can enhance the durability and lifespan of gears by ensuring that they meet stringent performance specifications.

Furthermore, AISI 9310 steel has emerged as a preferred material in aerospace gear manufacturing due to its remarkable mechanical properties. Enhanced carburization efficiency has been achieved through techniques like pre-ultrasonic shot peening, resulting in improved surface hardness and wear resistance. In the context of lightweight gear design, studies utilizing nonlinear finite element methods have provided insights into minimizing transmission errors, further contributing to the precision required in engineering applications. These advancements underscore the importance of both material selection and manufacturing methodologies in fulfilling the demands of modern precision engineering.

Analyzing Performance Metrics to Choose the Right Bevel Gears

When selecting bevel gears for precision engineering applications, assessing performance metrics is critical. Key performance indicators such as efficiency, load capacity, and wear resistance significantly influence gear selection. According to the American Gear Manufacturers Association (AGMA), the efficiency of bevel gears can vary dramatically, with high-performance gears achieving efficiencies above 98%. Therefore, understanding the operational requirements is essential to ensure the gears can handle the intended loads without compromising performance.

Tips: Always check the material specifications of the bevel gears. For high-wear applications, consider gears made from alloy steels or other advanced materials that offer superior fatigue resistance.

Additionally, consider the gear ratio and its impact on speed and torque. A suitable gear ratio will not only optimize power transmission but also enhance the lifespan of the gears. Recent studies have shown that an optimal gear ratio can improve torque output by up to 20%, thereby maximizing the efficiency of the system.

Tips: Utilize simulation software to model gear interactions and analyze performance under varied conditions, allowing for data-driven decision-making to fine-tune gear selection.

Related Posts

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

How to Choose the Right Ejector Pins for Your Injection Molding Projects

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation