10 Essential Tips for Working with Titanium Alloy

Titanium alloy is a remarkable material known for its strength and lightweight properties. However, working with titanium alloy can be challenging. It requires specific techniques and knowledge. Understanding its unique characteristics is crucial for successful application.

When handling titanium alloy, attention to detail is essential. Factors such as temperature and tooling can greatly impact the results. Many newcomers underestimate these aspects, leading to errors. Mistakes can be costly and time-consuming. Awareness of the specific needs of titanium alloy is vital in avoiding these pitfalls.

Emphasizing quality is crucial when selecting titanium alloy for projects. Each grade has distinct properties. Knowing these differences can prevent issues during assembly and fabrication. Moreover, keeping not just the technical aspects, but also the limitations of titanium alloy in mind can lead to better outcomes.

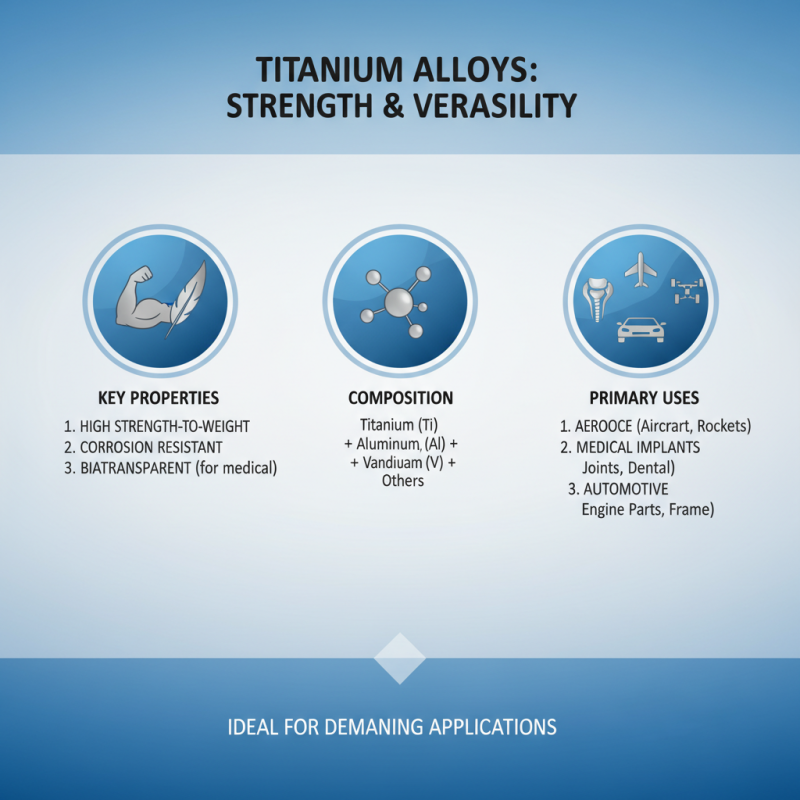

Understanding Titanium Alloys and Their Properties

Titanium alloys are unique materials known for their exceptional strength-to-weight ratio. Their lightweight nature makes them ideal for applications in aerospace, medical implants, and automotive components. These alloys combine titanium with other metals like aluminum and vanadium. This enhances their strength and corrosion resistance. Understanding their properties is vital for effective use.

Working with titanium alloys can be challenging. The material is difficult to machine due to its toughness. Moreover, it can generate excessive heat during processing, leading to work hardening. Workers often face issues with tool wear, which may require frequent replacements. Smaller tools may break easily, causing interruptions in production.

Another aspect to consider is the welding process. Titanium can be sensitive to contamination. Proper preparation is essential, as even small impurities can affect the final product. Crafting with titanium alloys requires attention to detail. Mistakes can lead to costly rework or failures in critical applications. Being aware of these challenges can lead to better results in projects involving titanium alloys.

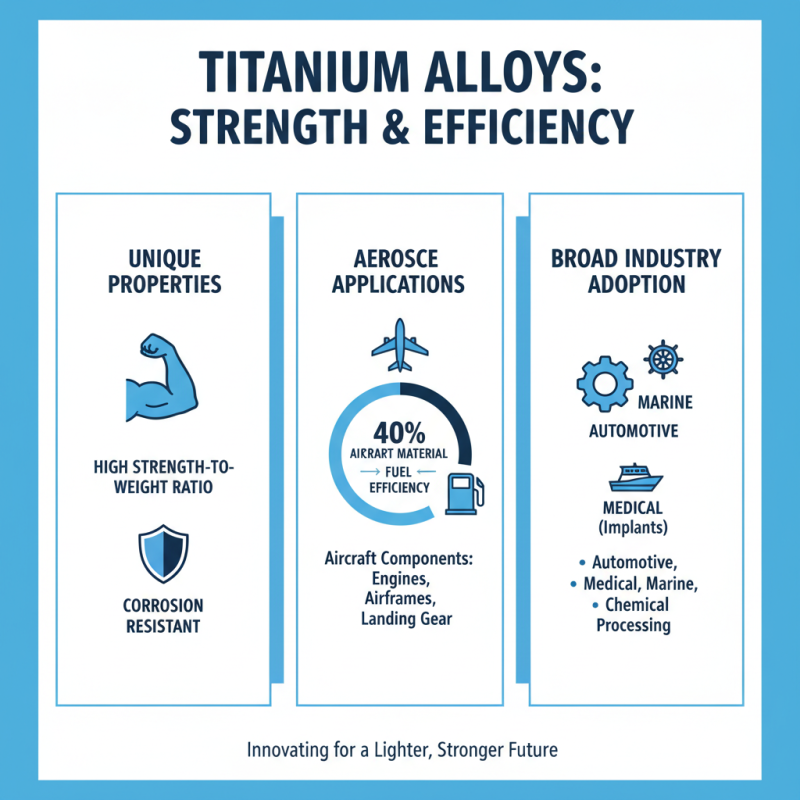

Common Applications of Titanium Alloys in Industry

Titanium alloys have become increasingly popular across various industries due to their unique properties. These alloys are known for their high strength-to-weight ratio. In the aerospace sector, for instance, they are extensively used in aircraft components. Approximately 40% of the material used in commercial aircraft is titanium alloy. This is significant as it helps reduce weight, thereby increasing fuel efficiency.

Another common application is in the medical field. Titanium alloys are widely used in implants because of their biocompatibility. Over 80% of orthopedic implants incorporate titanium materials. This is crucial for patients requiring surgical procedures. However, the cost of titanium alloy production remains high. Manufacturers must consider this in their budgeting.

The automotive industry also employs titanium alloys. With the drive towards lightweight vehicles, the use of titanium is expanding. Yet, the challenges in machining titanium can lead to production inefficiencies. Research indicates that titanium's toughness makes it harder to work with. Reflecting on these aspects helps companies strategize better.

Best Practices for Machining Titanium Alloys

Machining titanium alloys requires precision. These materials are known for their strength-to-weight ratio. Yet, they can be challenging to work with. A report from the International Journal of Machine Tools and Manufacture highlights that improper machining can lead to tool wear rates that are 10 times higher than those experienced with aluminum.

Cutting speeds are crucial. Recommendations suggest speeds of 30 to 50 meters per minute. But many operators push beyond this limit. The high thermal conductivity of titanium can lead to overheating and tool failure. Using the right coolant is essential. Studies show that a flood cooling method reduces the risk of thermal damage significantly.

Tool selection is vital. Carbide tools often perform best. However, many machinists overlook this. As a result, they face increased costs and downtime. The inconsistency in machining practices leads to varying quality. A consistent approach can improve outcomes. Although titanium alloys present difficulties, mastering techniques can enhance productivity.

10 Essential Tips for Working with Titanium Alloy

This bar chart illustrates the essential machining parameters for working with titanium alloys. The values represent optimal conditions for each parameter to achieve efficient and effective results while machining titanium.

Welding Techniques for Titanium Alloys

Welding titanium alloys presents unique challenges for technicians. Titanium's high reactivity with oxygen can lead to issues like embrittlement. According to a report by ASTM International, even a small amount of oxygen can severely degrade the mechanical properties of titanium. Thus, maintaining an inert atmosphere during welding is crucial. Techniques such as Gas Tungsten Arc Welding (GTAW) are commonly recommended due to their precision and control.

When welding titanium, attention to detail is essential. Pre-weld cleaning is needed to remove oxides and contaminants. A study by the International Journal of Metalworking highlighted that improper cleaning can lead to poor weld quality. Additionally, it is vital to monitor the heat input closely. Excessive heat can warp the material, causing structural weaknesses.

Post-weld heat treatment might be necessary, but it can create a different set of problems. While it helps relieve stresses, it can also promote the formation of beta phases, which affect strength. Each welding project can offer learning experiences. Reacting to mistakes is part of mastering these techniques.

Surface Treatment Methods for Enhanced Titanium Alloy Performance

When it comes to titanium alloys, surface treatment is crucial. Proper treatment can significantly enhance the mechanical properties and corrosion resistance. One effective method is anodizing. This process creates a protective oxide layer, improving wear resistance and aesthetic appeal. However, the thickness of the oxide layer can vary, affecting overall performance.

Another treatment worth considering is shot peening. This technique introduces compressive stresses on the surface, which can prevent fatigue failure. It’s a meticulous process and requires careful control. Overdoing it can lead to unintended surface roughness, which might compromise part functionality.

Lastly, the use of chemical treatments like passivation can enhance corrosion resistance. This method removes free iron and creates a uniform surface. Yet, achieving a consistent result can be challenging. Variations in application time and concentration can lead to less-than-ideal outcomes. Ensure thorough testing to validate the results after any treatment. Each method has potential pitfalls, so continuous evaluation is key.

10 Essential Tips for Working with Titanium Alloy - Surface Treatment Methods for Enhanced Titanium Alloy Performance

| Tip No. | Surface Treatment Method | Benefits | Applicable Industries |

|---|---|---|---|

| 1 | Anodizing | Enhanced corrosion resistance and aesthetic finish. | Aerospace, Automotive |

| 2 | Shot Peening | Increased fatigue resistance and surface hardness. | Aerospace, Medical |

| 3 | Chemical Vapor Deposition (CVD) | Improved wear resistance and thermal stability. | Manufacturing, Oil and Gas |

| 4 | Plasma Nitrocarburizing | Enhanced hardness and corrosion resistance. | Automotive, Aerospace |

| 5 | Coating with Ceramic | Superior wear resistance and thermal protection. | Aerospace, Industrial |

| 6 | Sandblasting | Removes surface contaminants and improves adhesion for coatings. | Manufacturing, Construction |

| 7 | Electropolishing | Achieves a smooth surface and reduces micro-corrosion. | Medical, Food Processing |

| 8 | Laser Surface Treatment | Enhanced surface properties and custom patterns. | Automotive, Aerospace |

| 9 | Cold Spray Coating | Adds material for superior repair and surface enhancement. | Aerospace, Energy |

| 10 | S hot Forming | Improved formability with minimized residual stress. | Manufacturing, Defense |

Related Posts

-

10 Essential Tips for Selecting Titanium Alloy: Insights from Industry Experts and Market Trends

-

10 Essential Tips for Using Titanium Alloys in Your Projects?

-

How to Achieve Super Finishing for Enhanced Surface Quality in Manufacturing

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Top 5 Industrial Applications of Technology You Should Know?

-

Revolutionizing Manufacturing: The Impact of Super Finishing Process on Product Quality and Efficiency