Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

In recent years, the landscape of modern manufacturing has undergone a significant transformation, driven by innovations in technology and a growing emphasis on sustainability. The global market for plastic components is projected to reach $650 billion by 2025, reflecting an urgent need for advancements that minimize environmental impact while maintaining performance. According to the Plastics Industry Association, nearly one-third of all manufacturing involves plastic components, highlighting their critical role in sectors such as automotive, electronics, and packaging. As manufacturers increasingly adopt eco-friendly materials and processes, the future of plastic components appears poised for a revolution, balancing the demands of efficiency and sustainability. This exploration delves into the latest innovations and strategies employed by industry leaders to address the dual challenge of performance and environmental responsibility, shaping a new era in manufacturing.

Innovative Materials Transforming Plastic Component Production

Innovative materials are fundamentally reshaping the production of plastic components, driving a significant shift towards sustainability in modern manufacturing. As highlighted by recent developments, research institutions play a pivotal role in this transformation, as seen with the leading Swiss institute focused on component design and recycling. Initiatives like the one in Dubai, which converts plastic waste from campuses into 3D printing materials, epitomize how the sector is innovatively addressing the global plastic challenge by turning waste into valuable resources.

Furthermore, advancements in recycling technologies are accelerating this shift. For instance, companies are successfully converting end-of-life plastics into high-quality feedstocks, significantly contributing to a circular economy. Notably, the world's largest recycler of high-density polyethylene and polypropylene demonstrates that transforming plastic waste can yield substantial raw materials for new products, underscoring the industry's commitment to sustainability. As the demand for eco-friendly alternatives rises, innovations like bio-based polymers from used cooking oil and materials produced from waste polystyrene highlight the growing potential of engineered solutions to create a sustainable future in plastic manufacturing.

Sustainable Practices in Modern Plastic Manufacturing Methods

Sustainable practices are becoming increasingly essential in modern plastic manufacturing methods. To address environmental concerns, manufacturers are shifting towards bio-based plastics, which are derived from renewable resources. This change not only reduces dependence on fossil fuels but also lessens the carbon footprint associated with plastic production. Implementing circular economy principles is another significant step forward; by designing products for recyclability, manufacturers can minimize waste and encourage the efficient reuse of materials.

Tips: Consider collaborating with suppliers who prioritize sustainable raw materials. Evaluate the entire supply chain to ensure each step adheres to eco-friendly practices. This can significantly enhance your brand image while supporting long-term environmental goals.

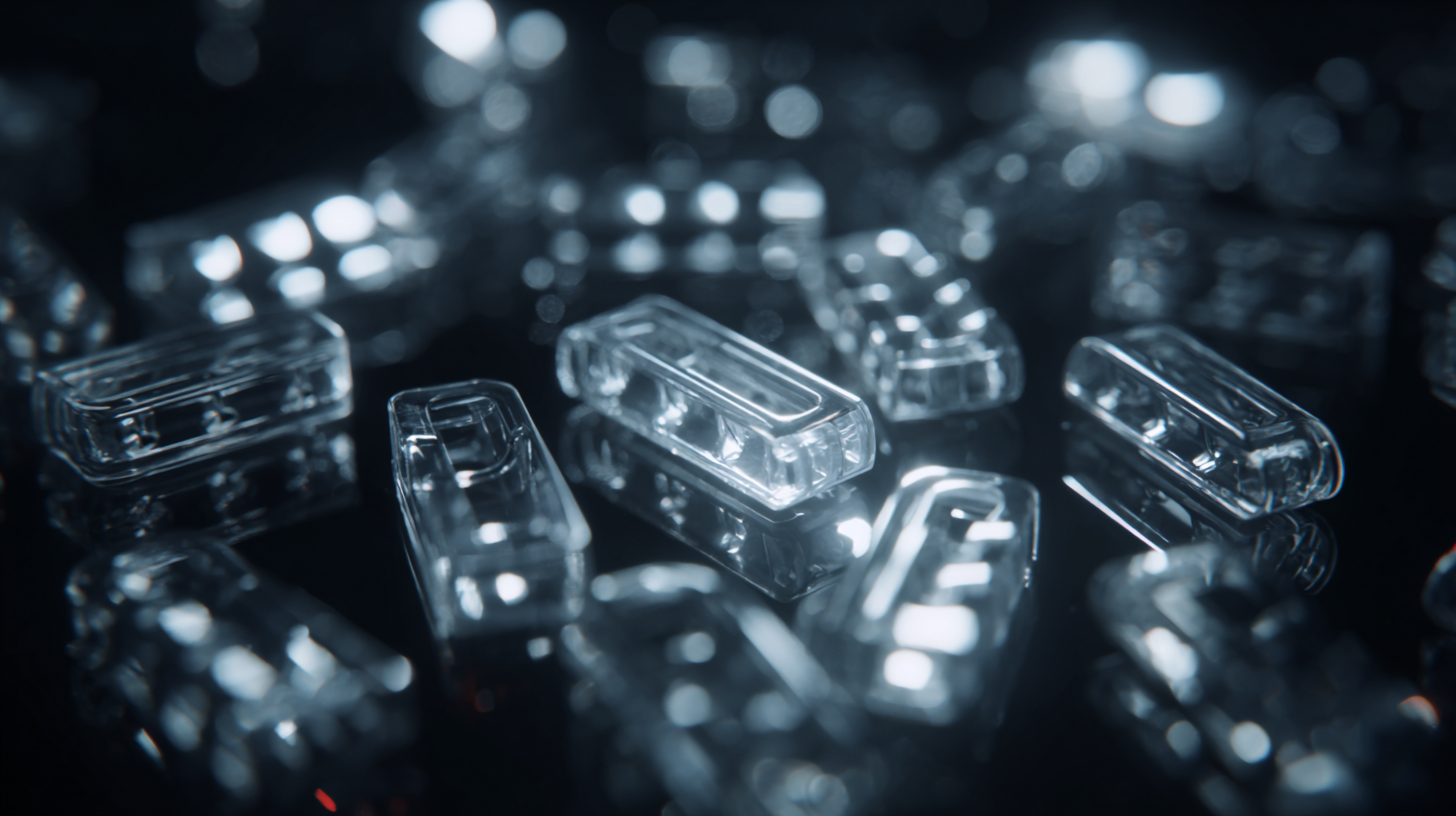

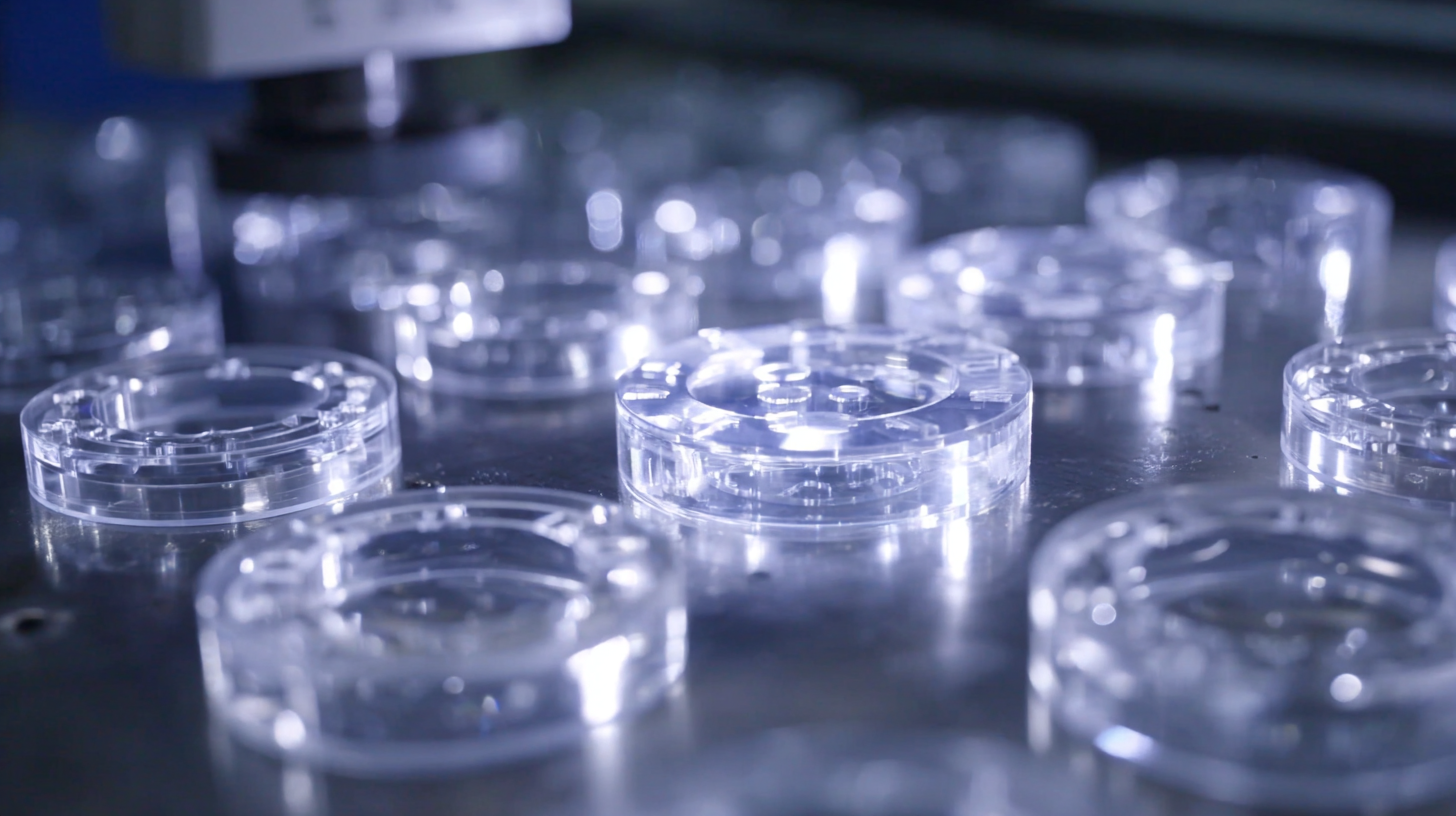

Furthermore, advancements in production technologies, such as 3D printing and injection molding using recycled materials, are paving the way for more resource-efficient practices. Companies are investing in research and development to innovate processing techniques that generate less waste and energy consumption. By adopting these technologies, manufacturers not only improve their sustainability metrics but also remain competitive in a rapidly transforming market.

Tips: Regularly review and update your manufacturing processes to incorporate the latest sustainable technologies. Keeping tabs on industry trends can provide insights into cost-saving measures while promoting environmental stewardship.

Digital Technologies Enhancing Plastic Design and Production Efficiency

In the rapidly evolving landscape of modern manufacturing, digital technologies are playing a pivotal role in enhancing plastic design and production efficiency. Innovative tools such as advanced simulation software and AI-driven analytics are enabling manufacturers to optimize their processes, reduce waste, and improve product quality. These technologies help streamline the entire lifecycle of plastic components, from design through to production and recycling, promoting a more sustainable approach to plastic usage.

**Tips:** Consider integrating digital solutions into your manufacturing process to improve efficiency. Utilize simulation tools to test various design variations before production, which can save both time and resources. Furthermore, adopting AI technologies can lead to better decision-making by analyzing large sets of data, allowing you to anticipate market trends and adjust production accordingly.

The rise of bioplastics is also a significant trend in the industry, driven by both consumer demand for sustainability and regulatory measures aimed at reducing environmental impact. By investing in bioplastic materials and the technologies that improve their production, companies can not only comply with tightening regulations but also position themselves as leaders in the shift toward greener manufacturing practices. Embracing such innovations will be crucial for manufacturers looking to thrive in a competitive and environmentally conscious market.

Innovations in Plastic Manufacturing: A Comparison of Technologies

This chart illustrates the percentage of manufacturers adopting various digital technologies within the plastic components industry. The data reflects the growing trend towards automation, 3D printing, and IoT integration, signaling a shift towards increased efficiency and sustainability in production.

Circular Economy Strategies for Plastic Component Lifecycle Management

The shift towards a circular economy is transforming the landscape of plastic component lifecycle management. By redefining the traditional linear model of production and disposal, manufacturers are now focusing on sustainable practices that enhance resource efficiency and reduce waste. This involves designing products with the end-of-life in mind, enabling easier disassembly, recycling, and remanufacturing. Innovations such as biodegradable plastics and the use of recycled materials are becoming more prevalent, allowing companies to minimize their environmental impact while still meeting consumer demands.

Additionally, effective lifecycle management strategies rely on collaboration across various stakeholders, including manufacturers, consumers, and recycling facilities. Implementing take-back programs and product-as-a-service models encourages responsible consumption and ensures that plastic components are reintegrated into the production cycle. By harnessing technology, such as advanced tracking systems, companies can better monitor the flow of materials, optimize recycling processes, and promote transparency in the supply chain. These strategies not only contribute to environmental sustainability but also enhance brand reputation and drive economic growth in a competitive market focused on sustainable innovation.

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing - Circular Economy Strategies for Plastic Component Lifecycle Management

| Innovation | Description | Sustainability Impact | Circular Economy Strategy |

|---|---|---|---|

| Biodegradable Plastics | Plastics that decompose naturally through microbial action. | Reduces landfill waste and pollution. | Design for Disassembly |

| Recycled Plastics | Utilization of post-consumer waste in new products. | Minimizes resource extraction and energy usage. | Closed-loop Recycling |

| 3D Printing with Plastics | Additive manufacturing using plastic filaments. | Reduces waste and allows for material efficiency. | On-demand Production |

| Bio-based Plastics | Plastics made from renewable biomass sources. | Decreases carbon footprint and reliance on fossil fuels. | Sustainable Sourcing |

| Smart Plastics | Plastics embedded with sensors for data collection. | Enhances functionality and reduces waste through improved tracking. | Lifecycle Monitoring |

Future Trends in Biodegradable Plastics and Their Applications

The biodegradable plastics market is witnessing substantial growth, with its value projected to reach $3.98 billion in 2024 from $3.76 billion in 2023, and expected to soar to $6.33 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.9%. This trend underscores a pivotal shift in consumer preferences towards sustainability, aligning with the global call for eco-friendly materials in manufacturing.

As China embarks on a strategic overhaul of its high-tech industries, biomanufacturing has been prominently included in the "14th Five-Year Plan." This initiative indicates a robust commitment to advancing sectors that prioritize sustainability and innovation. The integration of biomanufacturing into national strategy emphasizes the potential applications of biodegradable plastics across various fields, including packaging, textiles, and medical devices. This evolution not only aligns with environmental goals but also presents significant opportunities for economic growth as industries adapt to meet the rising demand for sustainable materials.

Related Posts

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations