Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing

The manufacturing landscape is undergoing a transformative shift, particularly in the realm of plastic parts, which are projected to dominate the production sector due to their versatility and cost-effectiveness. According to a recent report by Smithers, the global market for plastic parts is expected to reach approximately $700 billion by 2027, driven by advancements in materials science and additive manufacturing technologies. Innovations such as bioplastics, 3D printing, and automated processing techniques are not only enhancing the performance and sustainability of plastic components but also paving the way for smarter manufacturing processes. As industries strive to reduce waste and improve efficiency, the evolution of plastic parts will play a crucial role in shaping the future of manufacturing, addressing both economic and environmental challenges. This exploration delves into the latest innovations that are set to redefine the production of plastic components and their applications across various sectors.

The Evolution of Plastic Manufacturing Technologies

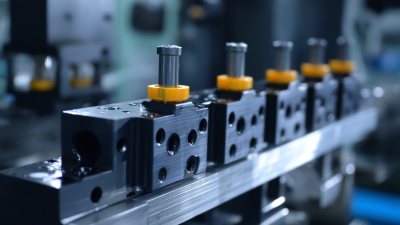

The evolution of plastic manufacturing technologies is fundamentally reshaping the industry landscape, driven by innovations that prioritize sustainability and efficiency. Recent developments indicate a trend toward companies aiming to integrate advanced solutions in their manufacturing processes. For example, the strategic acquisition of a tech firm focused on polyurethanes highlights the industry's drive to enhance production capabilities and offer a broader range of services. This shift is underscored by the introduction of low-pressure injection molding techniques, which promise not only to streamline manufacturing but also to significantly reduce environmental impact.

In parallel, advancements in sustainable production practices are becoming increasingly vital in meeting global demands. Companies are embarking on initiatives to incorporate renewable materials and improve recycling methods, even as some recyclers face challenges that threaten their viability. This dual focus on innovation and ecological responsibility signals a new chapter in plastic manufacturing technologies, where economic viability and environmental stewardship go hand in hand. The commitment to evolve in response to these challenges is evident across the industry, setting the stage for transformative changes that will shape the future of plastic production.

Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing

Sustainable Materials: Shaping the Future of Plastic Parts

The future of plastic parts is increasingly leaning towards sustainability as the industry grapples with the pressing need to mitigate environmental impacts. A broad-based collaboration among scientists from various sectors is crucial to find innovative solutions for reducing plastic pollution and transitioning towards a circular economy. Research indicates that only a fraction of plastic waste is properly managed, with up to 80% ending up in landfills or the environment. This highlights the urgent need for initiatives that not only focus on recycling but also on incorporating sustainable materials in production processes.

Innovations in biobased and biodegradable plastics are redefining the landscape of manufacturing. For instance, the biobased biodegradable plastic market is projected to grow from USD 6.3 billion in 2025 to approximately USD 15.6 billion by 2035, reflecting a significant shift towards greener alternatives.

Companies are exploring the use of recycled plastics in automotive applications, transforming waste materials into high-quality car components. This trend is echoed in the packaging industry, where efforts are being made to reduce virgin plastic usage while enhancing the recyclability of packaging materials. Such advancements are not only beneficial for the environment but also present a compelling business case for companies willing to invest in sustainable practices.

Advanced Manufacturing Techniques Enhancing Plastic Efficiency

The future of plastic parts manufacturing is being transformed by advanced techniques that enhance efficiency and sustainability. One of the foremost innovations is the adoption of 3D printing technology, which allows for precise design and rapid prototyping. This not only reduces material waste but also shortens production times, making it an attractive option for manufacturers looking to streamline their processes. Additionally, advancements in composite materials enable the creation of lighter and stronger plastic components, which is particularly beneficial in industries such as automotive and aerospace where performance and weight are crucial.

Another significant trend is the integration of automation and artificial intelligence in manufacturing processes. These technologies facilitate greater precision in the production of plastic parts, minimizing errors and maximizing output. Furthermore, smart factories leverage IoT devices to monitor and optimize the efficiency of manufacturing lines in real-time. By collecting data and analyzing performance metrics, manufacturers can make informed decisions to enhance their operational efficiency and reduce energy consumption. Overall, these advanced manufacturing techniques are not only reshaping the way plastic parts are produced but also paving the way for a more sustainable and efficient future in the industry.

3D Printing Innovations Revolutionizing Plastic Part Design

The landscape of manufacturing is undergoing a transformative shift, particularly in the realm of plastic part design. Recent advancements in 3D printing technologies are at the forefront of this evolution. According to a report by Gartner, the 3D printing market is expected to grow to $34.8 billion by 2024, indicating a significant increase in the adoption of these innovative techniques across industries. This technology not only enhances design flexibility but also reduces lead times, allowing for rapid prototyping and customization of plastic parts.

Tips: Consider investing in training for your team to ensure they are proficient in the latest 3D printing software and techniques. Staying updated with industry standards can greatly improve your manufacturing processes.

Furthermore, the introduction of advanced materials, such as bio-based plastics and reinforced polymers, is expanding the possibilities for 3D printed plastic components. A study by Smithers Pira estimates that the global market for 3D printing materials will reach $1.16 billion by 2027, showing a substantial demand for innovative solutions that meet sustainability goals. This evolution not only aims to enhance performance but also addresses the environmental concerns associated with traditional plastic manufacturing.

Tips: Explore partnerships with material suppliers who specialize in sustainable options, which can help your business align with eco-friendly practices while enhancing product performance.

Impact of Circular Economy on Plastic Production Practices

The concept of a circular economy is gaining traction, particularly within the plastic manufacturing sector. This approach emphasizes the importance of sustainability by advocating for the continuous reuse and recycling of materials, thereby minimizing waste. In the context of plastic production, this means shifting away from the traditional linear model—where products are made, used, and discarded—to a system that keeps plastics in circulation. Innovations in recycling technologies and bioplastics are spearheading this transformation, enabling manufacturers to reclaim and repurpose plastic waste efficiently.

Furthermore, the circular economy fosters collaboration across industries, encouraging companies to adopt eco-friendly practices. By developing closed-loop systems, manufacturers can not only reduce their environmental impact but also create new business models that prioritize sustainability. For example, designs for disassembly and modular components are being integrated into product development, allowing easier recycling and repair. As industries adopt these practices, they contribute to a broader cultural shift, promoting responsibility and awareness regarding plastic use, which is crucial for a more sustainable future in manufacturing.

Related Posts

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations