Why Choose Home Plastic Injection Molding for Your DIY Projects?

Home plastic injection molding is becoming an increasingly popular choice for DIY enthusiasts looking to create customized parts and products. As John Smith, a leading expert in the field of plastic manufacturing, notes, “Home plastic injection molding offers unparalleled flexibility and cost-effectiveness for hobbyists and small-scale producers alike.” This innovative technique allows individuals to transform their ideas into tangible objects with precision and ease, making it an attractive option for a variety of projects.

The rise of home plastic injection molding technology has made it more accessible than ever for those who wish to engage in hands-on creation. With affordable equipment and materials readily available, DIYers can produce high-quality, durable plastic items right at home. This not only provides a unique avenue for creativity but also empowers individuals to bring their designs to life without relying on traditional manufacturing processes.

In this article, we will explore the multiple benefits of home plastic injection molding for your DIY projects, delving into how it can enhance your crafting experience, save costs, and provide limitless design opportunities. Whether you’re a seasoned maker or just starting out, understanding the advantages of this method can help you take your DIY endeavors to the next level.

Benefits of Home Plastic Injection Molding for DIY Enthusiasts

Home plastic injection molding has gained significant traction among DIY enthusiasts due to its numerous benefits, transforming how hobbyists approach their projects. One of the primary advantages is the ability to produce high-quality, complex parts with precision. According to industry data, plastic injection molding can achieve tolerances as tight as ±0.01 mm, making it ideal for intricate designs that require a professional finish. This level of accuracy ensures that DIYers can create components that not only fit perfectly but also enhance the overall aesthetics of their projects.

Another compelling reason to adopt home plastic injection molding is cost-effectiveness. Reports indicate that while the initial setup costs may seem high, the long-term savings can be substantial, especially for those who frequently produce parts. With the ability to reuse molds and materials, enthusiasts can significantly reduce production costs per piece. Moreover, by utilizing readily available thermoplastics, DIYers can experiment with various designs without the fear of breaking the bank. This flexibility enables innovation and creativity, allowing hobbyists to bring their ideas to life with relative ease and efficiency.

Why Choose Home Plastic Injection Molding for Your DIY Projects?

| Benefit | Description | Example Use |

|---|---|---|

| Cost Efficiency | Reduce overall project costs by producing parts at home. | Making custom components for gadgets. |

| Customization | Easily modify designs to meet specific project needs. | Designing unique toys or prototypes. |

| Precision Manufacturing | High precision for intricate designs and repetitive production. | Creating parts for mechanical devices. |

| Scalability | Easily produce multiple copies of the same part. | Batch production of game pieces. |

| Speed of Production | Faster production timelines compared to manual techniques. | Rapid prototyping for design testing. |

| Material Variety | Ability to use different types of plastics for various applications. | Choosing the right plastic for durability or flexibility. |

Understanding the Basics of Plastic Injection Molding Processes

Plastic injection molding is a versatile manufacturing process that allows for the efficient production of intricate plastic parts. At its core, this technique involves injecting molten plastic into a pre-designed mold, where it cools and solidifies to form the desired shape. Understanding the basics of this process can significantly enhance your DIY projects, whether you’re aiming to create custom components or prototypes.

The injection molding process begins with the selection of a suitable thermoplastic material, which is heated until it reaches a liquid state. Once melted, the plastic is forced into a mold under high pressure. This critical step ensures that every detail of the mold is captured, resulting in parts that are consistent in quality and precision. After the material cools and hardens, the mold opens, and the finished component is ejected. This method is not only efficient but also allows for repeatability, making it ideal for creating multiple copies of the same part without compromising quality.

For DIY enthusiasts, the ability to create custom molds gives an added layer of creativity and personalization to projects. By mastering the fundamental principles of plastic injection molding, anyone can transform their ideas into tangible products, all from the comfort of their home workshop. This process opens up a realm of possibilities, enabling innovative designs that were once limited to industrial production.

Advantages of Home Plastic Injection Molding for DIY Projects

Essential Equipment and Tools for Home Plastic Injection Molding

Home plastic injection molding is becoming increasingly popular among DIY enthusiasts, providing an efficient way to create custom plastic components. To embark on this creative journey, it's essential to equip yourself with the right tools and equipment. A high-quality injection molding machine is the centerpiece of your setup. According to a recent market report, the global injection molding machine market is expected to grow at a CAGR of 4.1% from 2021 to 2028, underscoring the growing interest in this technology for both commercial and residential use.

In addition to the injection molding machine, you'll need several key tools: a heated hopper, temperature control units, molds, and safety gear like gloves and goggles. Molds can be either pre-made or custom-made using CAD software, allowing for a myriad of designs. A meticulous approach to temperature settings is crucial; maintaining the correct temperature can reduce defects and improve the quality of the final product. A report from the Plastics Industry Association suggests that precise temperature control can enhance production efficiency by up to 25%.

Tips: Start with small projects to familiarize yourself with the machine and its capabilities. Experimenting with different materials can also yield interesting results—polypropylene and polystyrene are great choices for beginners due to their accessibility and ease of use. Always prioritize safety; the temperature of the molten plastic can exceed 200°C, so proper protective gear is a must.

Common Applications of Plastic Injection Molding in DIY Projects

Plastic injection molding has become a popular choice for DIY enthusiasts, thanks to its versatility and efficiency. According to a report by Grand View Research, the global plastic injection molding market is expected to reach $438 billion by 2025, highlighting its growing relevance in various sectors, including home projects. DIYers can leverage this technology to create everything from custom parts for household repair to intricate designs in home decor. The precision that injection molding offers not only reduces material waste but also enhances the quality and durability of the finished products.

Common applications of plastic injection molding in DIY projects include making personalized fixtures, unique storage solutions, and even functional prototypes for inventions. For instance, many hobbyists use injection molding to create replacement components for appliances or vehicles, ensuring a perfect fit and function. Furthermore, the ability to design complex geometries opens up possibilities for artistic creations and unique designs that standard manufacturing cannot achieve. Reports suggest that over 70% of DIY homeowners have engaged in projects that incorporated 3D-printed or molded components, emphasizing the technology's accessibility and growing adoption in home crafting activities.

Tips for Successful Home Plastic Injection Molding Techniques

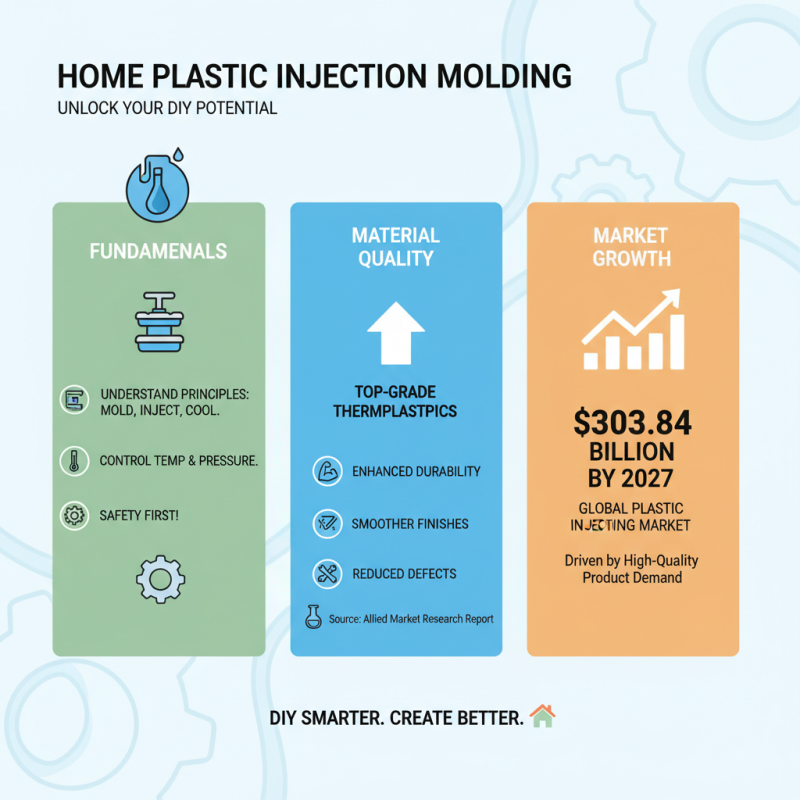

Home plastic injection molding is a fascinating technique that opens a new realm of possibilities for DIY enthusiasts. To achieve success in your home projects, it’s crucial to understand the fundamental principles and best practices involved in this process. One essential tip is to ensure the quality of your materials. According to a report from Allied Market Research, the global plastic injection molding market is expected to hit $303.84 billion by 2027, driven by the increasing demand for high-quality plastic products. Utilizing top-grade thermoplastics not only enhances the durability of your products but also ensures smoother finishes and reduced defects in the molding process.

Another significant factor is mastering the injection molding parameters. Adjusting parameters such as temperature, pressure, and cooling time can drastically influence the quality of your final products. Industry standards indicate that a well-calibrated process can improve production efficiency by up to 30%, thereby reducing waste and maximizing outputs. Beginners should start with smaller molds and less complex designs to fine-tune their techniques. As experience grows, experimenting with varied resin types and custom mold designs can lead to innovative applications, further enhancing your DIY ventures.

Related Posts

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

10 Essential Tips for Selecting Titanium Alloy: Insights from Industry Experts and Market Trends

-

How to Choose the Right Bevel Gears for Your Precision Engineering Needs

-

Top Benefits of Micro Machining for Precision Engineering Applications

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation