Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

As the global manufacturing landscape evolves, the significance of the plastic injection mold industry continues to rise, with projections indicating a market growth rate of over 5% annually through 2027. The 2025 China Import and Export Fair, known as the 138th Canton Fair, serves as a pivotal platform for showcasing these advancements. Recent reports highlight that the plastic injection mold market is projected to reach approximately $28 billion by 2025, driven by increasing demand across sectors such as automotive, consumer goods, and electronics. Innovations in plastic injection molds, including the implementation of advanced materials and smart manufacturing technologies, are reshaping production efficiencies and product quality. This fair will not only exhibit cutting-edge mold designs and techniques but also facilitate international collaboration, vital for enhancing competitiveness in a globalized economy.

Innovative Materials in Plastic Injection Molds at the 2025 Fair

At the 2025 China Import and Export Fair, the spotlight on

plastic injection molds is

largely attributed to the innovative materials that are reshaping

the manufacturing landscape. The industry is witnessing a surge in

the use of advanced

composites and thermoplastic

elastomers, which offer enhanced durability and flexibility

compared to traditional materials. These innovations not only improve

the quality of molded products but also increase efficiency in

production processes, allowing manufacturers to reduce waste and

lower costs.

Furthermore, the fair highlights the growing trend of

sustainable materials

in plastic injection molding.

Biodegradable polymers and

recycled plastics are gaining

traction as industries become more environmentally conscious.

Exhibitors are showcasing how these sustainable alternatives can

maintain performance while significantly reducing the ecological

footprint of manufacturing. As businesses seek to align with global

sustainability goals, the integration of such materials in plastic

injection molds underscores a pivotal shift towards

responsible production

practices.

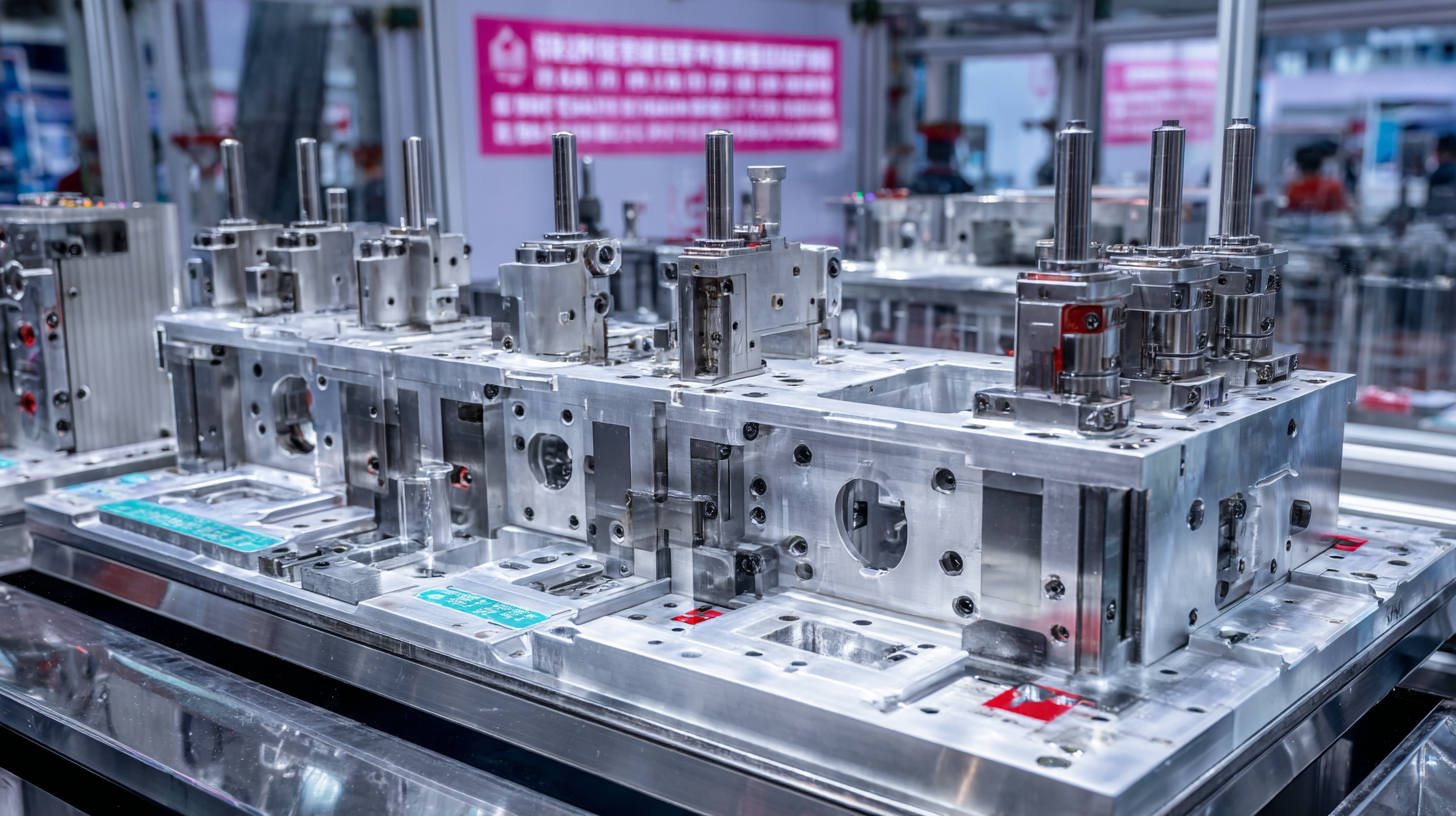

Cutting-Edge Technologies Revolutionizing Mold Design and Production

The 2025 China Import and Export Fair serves as a significant platform for showcasing advancements in plastic injection molding technologies. This year, the spotlight is on cutting-edge innovations that are revolutionizing mold design and production processes. With the introduction of advanced materials and sophisticated manufacturing techniques, mold designers are now able to create lighter, stronger, and more precise components, significantly enhancing the productivity and efficiency of manufacturing operations.

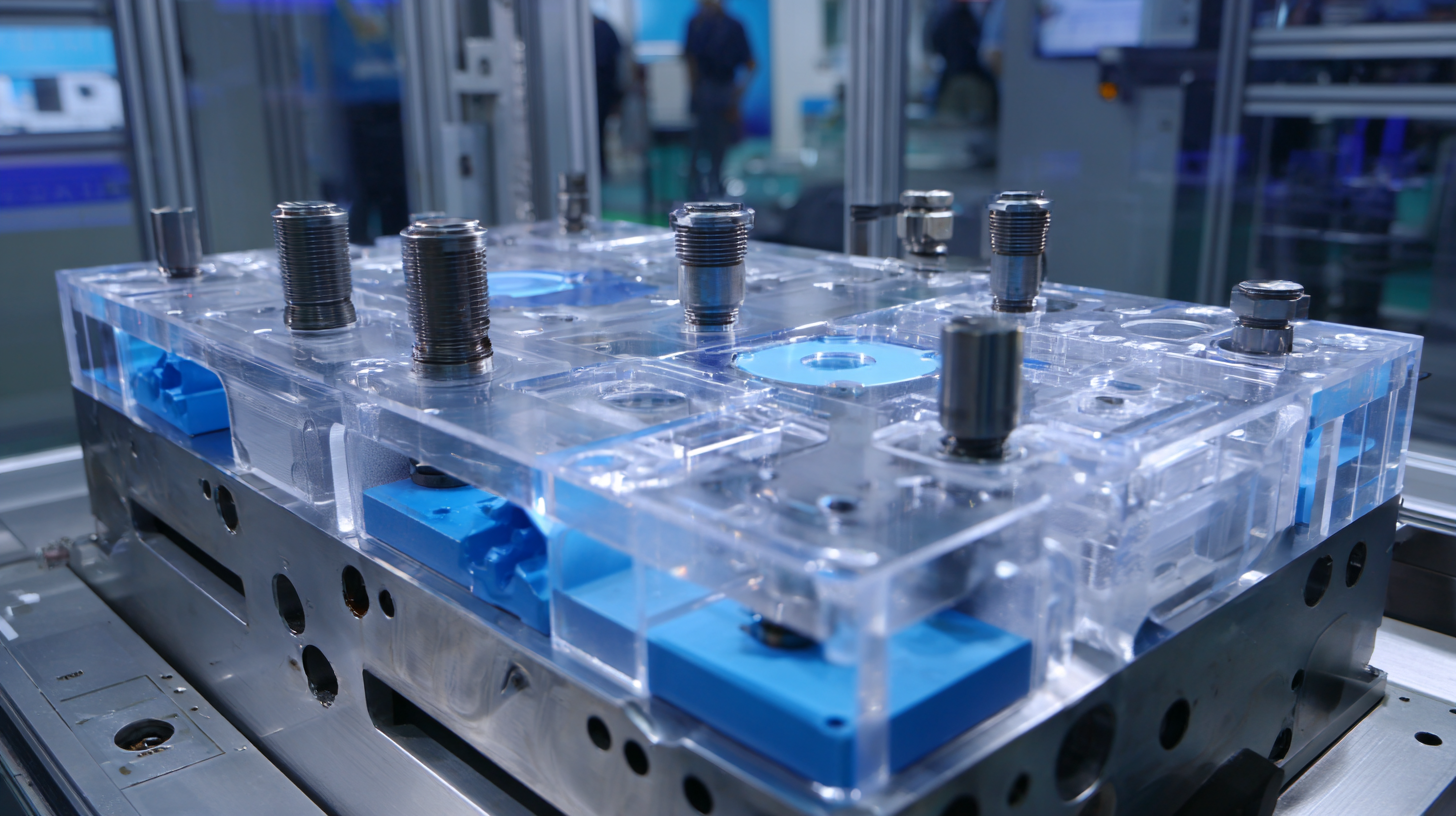

Among the most notable innovations are the applications of 3D printing and computer-aided design (CAD) in mold creation. These technologies allow for rapid prototyping and streamlined adjustments, enabling manufacturers to reduce lead times and costs dramatically. Automated solutions, powered by artificial intelligence, are also gaining traction, optimizing the entire production cycle from initial design through to finished product, thus minimizing human error and maximizing output quality. As these breakthroughs continue to unfold, they promise to shape the future of the plastic injection molding industry, catering to an increasingly diverse array of applications and driving economic growth.

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

| Category | Technology | Applications | Advantages |

|---|---|---|---|

| 3D Printing Integration | Additive Manufacturing | Prototype Development | Faster production, cost-effective prototypes |

| Smart Molds | IoT Sensors | Real-time Monitoring | Increased efficiency, reduced defects |

| Lightweight Materials | Advanced Composites | Automotive & Aerospace | Improved fuel efficiency, reduced weight |

| Biodegradable Plastics | Eco-friendly Materials | Consumer Goods | Sustainable options, reduced environmental impact |

| Enhanced Cooling Systems | Conformal Cooling | Injection Molding Processes | Shorter cycle times, improved quality |

Sustainability Trends in Plastic Injection Molding Innovations

At the forefront of the manufacturing industry, plastic injection molding has undergone significant innovations, particularly in the realm of sustainability. According to a recent market report by Grand View Research, the global market for sustainable plastics is projected to reach USD 401.24 billion by 2027, reflecting a growing demand for environmentally friendly materials in various industries. The focus on sustainability in plastic injection molds not only enhances the longevity of the products but also minimizes waste, which aligns with current environmental goals.

Additionally, companies are increasingly investing in biodegradable and recyclable materials, which can considerably reduce the carbon footprint associated with traditional plastics. Eco-friendly alternatives made from plant-based resins are gaining traction, with a study by the Polymer Polymer Composites journal showing that these materials can reduce energy consumption in the manufacturing process by up to 30%. As we explore innovations showcased at the 2025 China Import and Export Fair, it will be interesting to see how manufacturers integrate these sustainable practices into their injection mold designs, setting a precedent for future developments in the industry.

Impact of Automation on Efficiency in Mold Manufacturing Processes

The impact of automation on efficiency in mold manufacturing processes is a critical aspect of modern production environments, particularly highlighted at the 2025 China Import and Export Fair. As manufacturers increasingly adopt automated solutions, the integration of advanced technologies such as 6-axis robots has revolutionized injection molding processes. These robots not only improve precision but also enhance the speed and efficiency of mold production, allowing manufacturers to achieve higher output rates while reducing labor costs.

Moreover, innovations like automated systems for plastic injection molds are pivotal in addressing design deficiencies early in the production process. By incorporating intelligent automation, manufacturers can optimize injection molding parameters and significantly improve part quality, which is essential for competitive advantage in the market. Advances in automation not only streamline workflow but also ensure a more sustainable approach to manufacturing, minimizing waste and enhancing resource utilization. As the industry moves towards greater automation, the potential for increased efficiency and environmental responsibility becomes ever more attainable.

Impact of Automation on Mold Manufacturing Efficiency

This chart illustrates the efficiency improvements in plastic injection mold manufacturing processes with varying levels of automation over a five-year period.

Showcasing Global Leaders in Plastic Injection Mold Innovations

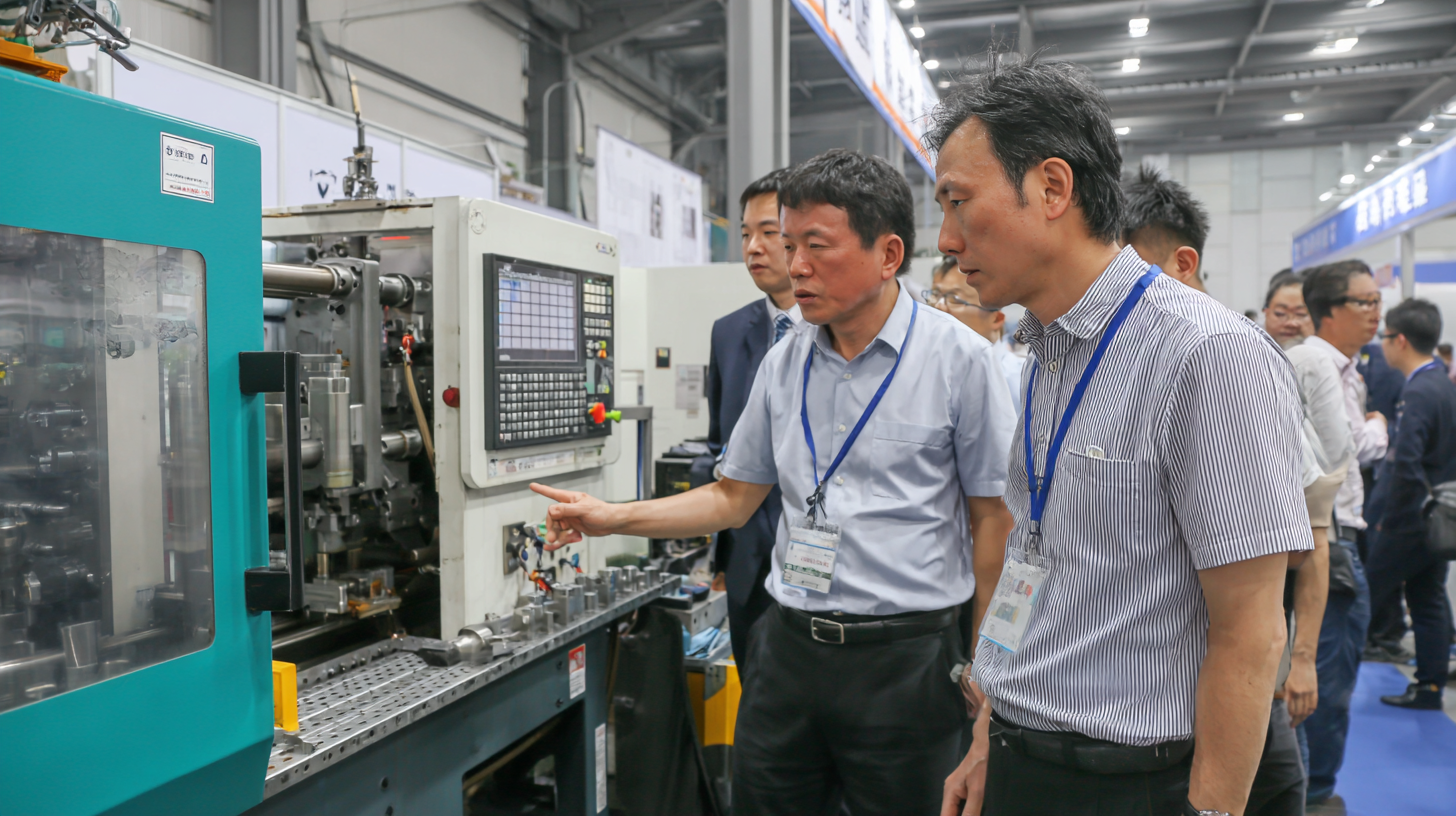

The 2025 China Import and Export Fair is set to become a pivotal platform for the global plastic injection mold industry, showcasing the latest innovations from leading manufacturers around the world. This prestigious event will gather industry giants who are at the forefront of designing and producing advanced injection molding technologies. Exhibitors will unveil cutting-edge solutions that enhance efficiency, precision, and sustainability, attracting manufacturers eager to upgrade their production processes.

Among the notable exhibitors, companies renowned for their commitment to research and development will present groundbreaking methods for reducing material waste and energy consumption during the molding process. Visitors will have the opportunity to engage with these global leaders, gaining insights into how these innovations can be integrated into their own operations. The fair promises to facilitate valuable exchanges of ideas, driving the industry forward in a collaborative environment that fosters technological advancement and fosters relationships among international stakeholders.