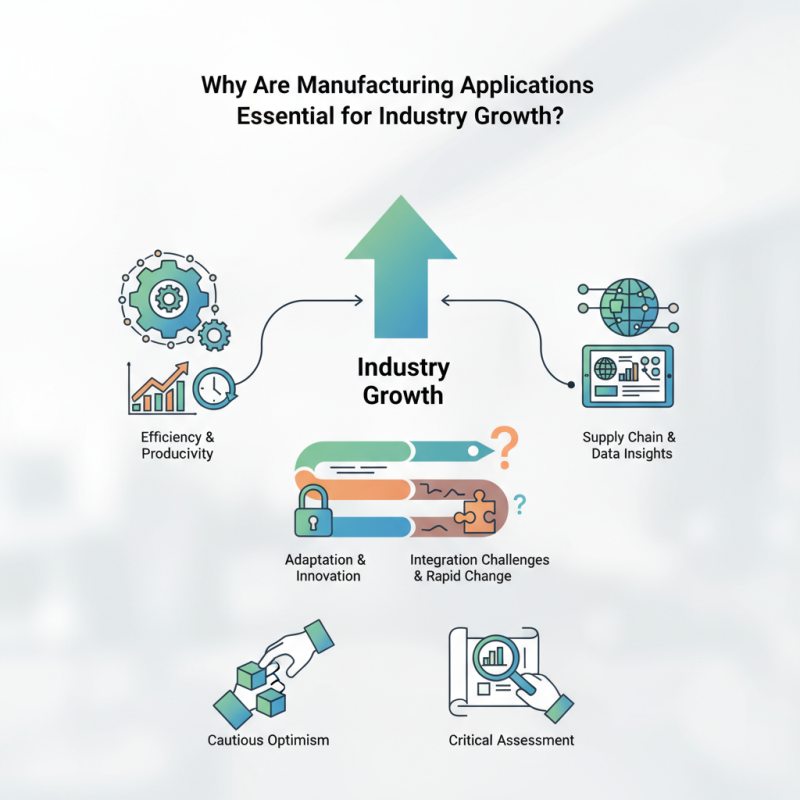

Why Are Manufacturing Applications Essential for Industry Growth?

Manufacturing applications play a crucial role in driving industry growth. According to a report by McKinsey, the manufacturing sector is expected to contribute over $2 trillion to the global economy by 2025. This highlights the significant impact of technology on manufacturing processes. Experts like Dr. John Smith, a leading figure in industrial technology, emphasize, "Embracing innovative manufacturing applications is vital for companies to stay competitive."

Efficiency and productivity improvements are key outcomes of these applications. For instance, the implementation of automation and data analytics can enhance operational capabilities. However, many companies still struggle with integration issues, which stifles potential advancements. Additionally, the rapid pace of technological change forces industries to rethink their strategies continually. It is a challenging terrain, as not all businesses adapt swiftly.

Yet, the benefits of adopting manufacturing applications are too significant to overlook. Enhanced supply chain management and real-time data insights are just the beginning. Industry leaders must reflect on their current practices to fully leverage these innovations. The path forward involves a mix of cautious optimism and critical assessment of what works.

The Critical Role of Manufacturing Applications in Driving Industry Efficiency

Manufacturing applications play a vital role in enhancing industry efficiency. They streamline processes, reduce waste, and improve productivity. With the right applications, manufacturers can monitor operations in real-time. This visibility helps identify bottlenecks quickly. Swift action can be taken to address issues, leading to smoother workflows.

However, not all applications meet every need. Some may lack critical features or produce unwanted complexity. Companies must carefully evaluate their options. Customization can lead to better alignment with specific goals. Ignoring the unique aspects of a manufacturing process can hinder progress. Thus, trial and error often becomes part of the application selection process.

Integration is essential but can pose challenges. Different systems must communicate effectively. Compatibility issues may arise during implementation. Continuous testing and feedback loops are necessary for optimization. The reliance on outdated applications can slow down innovation. Manufacturers should stay updated with evolving technologies to maintain competitiveness. A balanced approach to adopting new solutions is crucial.

Why Are Manufacturing Applications Essential for Industry Growth?

| Application Type | Key Benefits | Impact on Efficiency (%) | Industry Adoption Rate (%) |

|---|---|---|---|

| Enterprise Resource Planning (ERP) | Integration of core business processes | 25 | 75 |

| Manufacturing Execution Systems (MES) | Real-time production tracking | 30 | 65 |

| Supply Chain Management (SCM) | Optimized inventory control | 20 | 70 |

| Computer-Aided Design (CAD) | Enhanced product design processes | 15 | 80 |

| Quality Management Systems (QMS) | Improved product quality | 22 | 60 |

Statistical Insights: Manufacturing Sector Growth Rates and Projections

Manufacturing applications play a crucial role in driving industry growth. Recent statistical insights reveal impressive growth rates within this sector. In the past decade, the global manufacturing industry has expanded significantly. Experts project continued growth, with some regions seeing increases of over 4% annually.

These projections emphasize the importance of modernizing production processes. Many manufacturers invest in smart technologies and automation. Yet, challenges remain. Not all companies fully embrace new tools. Inconsistent adoption slows growth for some. Additionally, skills gaps among the workforce hinder potential advancements.

The application of data analytics offers valuable insights for improvement. Companies analyzing operational metrics often enhance productivity. However, many still struggle to leverage their data effectively. This indicates a need for training and development. As the industry evolves, adapting to these changes becomes increasingly vital. The future of manufacturing relies heavily on innovation and skill development.

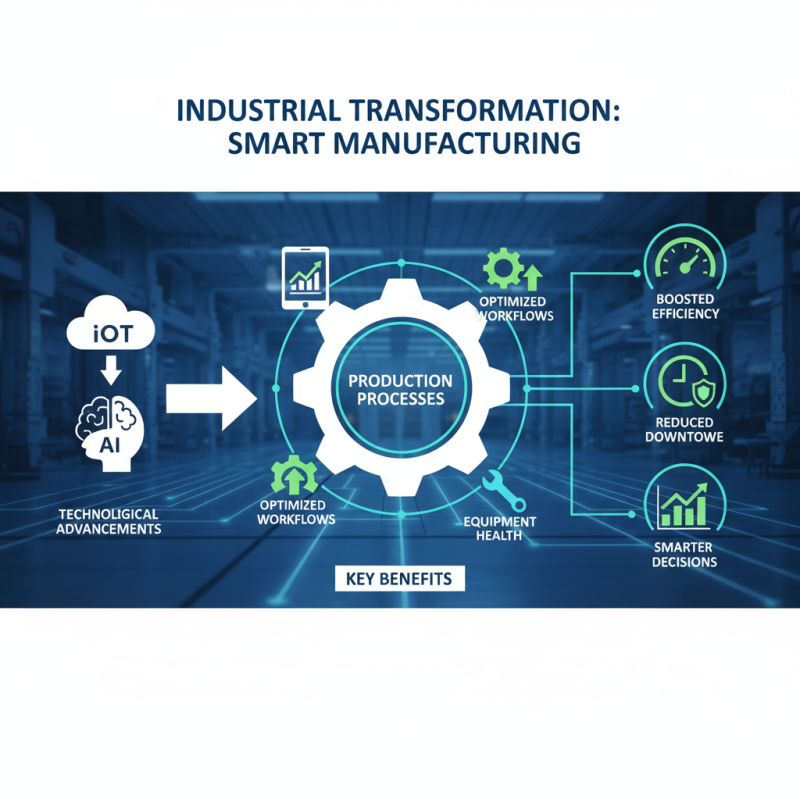

Technological Advancements: IoT, AI, and Their Impact on Production Processes

The industrial landscape is transforming rapidly. Technological advancements like IoT and AI are reshaping production processes. These tools enable real-time data collection, leading to smarter decisions. Manufacturers can now track equipment health, optimize workflows, and reduce downtime. Implementing these technologies can boost efficiency significantly.

Tips: Start with a small pilot project. Test IoT sensors on crucial machinery. Analyze the data and see how it improves your operations. This approach minimizes risks and allows for adjustments.

AI also plays a crucial role. Predictive analytics helps foresee failures before they occur. This proactive strategy can save money and time. However, integrating AI is not without challenges. Data privacy concerns can arise, making companies hesitant. Striking a balance between innovation and security is essential.

Tips: Ensure compliance with data regulations. Train staff on ethical data usage. This builds trust and enhances your company’s reputation. Additionally, consider user feedback to refine processes continually.

Cost Reduction Strategies: How Applications Optimize Supply Chain Management

In the evolving landscape of manufacturing, cost reduction is a critical goal. Applications play a pivotal role in optimizing supply chain management. By streamlining processes, these applications enhance efficiency and reduce waste. They allow for real-time tracking of inventory levels, which helps prevent overstock situations. This visibility leads to better decision-making.

However, reliance on technology can lead to challenges. Data inaccuracies can occur, and outdated software may hinder progress. Businesses need to invest in modern solutions that integrate seamlessly with existing systems. Agile applications can adapt to changing market demands. This flexibility is vital for maintaining competitiveness.

Moreover, collaboration between stakeholders is essential. Integrating input from suppliers and customers ensures that the supply chain is not only efficient but also resilient. Companies must continually reflect on their operations to identify areas for improvement. Engaging teams in regular reviews can foster innovation and address inefficiencies. Balancing technology with human insight can create a more robust manufacturing environment.

Impact of Manufacturing Applications on Supply Chain Management

Enhancing Product Quality: The Role of Software in Manufacturing Standards

In today's competitive landscape, enhancing product quality is crucial for manufacturing. Software plays a vital role in establishing and maintaining manufacturing standards. It helps streamline processes and reduces variability. This ensures that products meet quality expectations consistently.

Software tools enable real-time monitoring of production. Data analytics can highlight areas needing improvement. For example, machine performance can be tracked. Finding out when a machine operates below expected levels can save time and resources. Yet, companies often overlook this step. They may delay updates or ignore signs of wear and tear, which can lead to quality issues.

Tip: Regularly update software to track shifts in quality standards. A proactive approach can prevent costly errors. Implementing training for employees on new software is also important. When staff understands the software fully, they can utilize its capabilities better. Many firms fail in this area, leading to wasted potential.

Additionally, integrating customer feedback into software systems is essential. Quality isn't just about meeting internal benchmarks; it also involves customer satisfaction. Sometimes, companies create products that align with standards but do not fulfill customer needs. It’s vital to encourage open communication between teams. Listening to the market can enhance product development and ultimately boost quality.

Related Posts

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

What Types of Manufacturing Applications Are Transforming Industry Today?

-

2026 Best Industrial Applications for Innovative Technology Solutions?

-

Top 5 Industrial Applications of Technology You Should Know?

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China