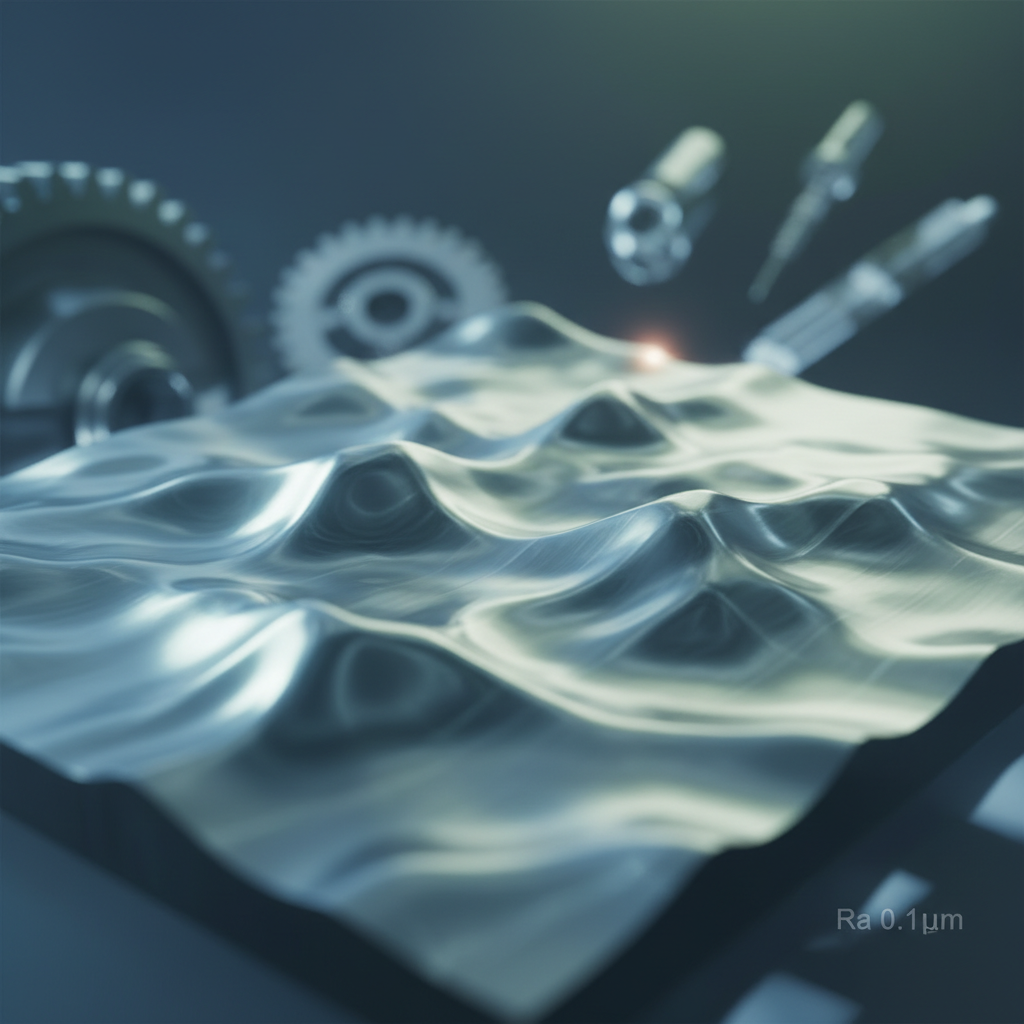

Why Super Finishing Is Essential for Achieving a Surface Roughness of Up to Ra 0.1µm

Super finishing is a critical process in achieving superior surface quality, particularly in applications where precision and performance are paramount. As noted by Dr. Emily Carter, a leading expert in surface engineering, "Super finishing not only enhances the aesthetic appeal of components but also significantly improves their functional performance." This underscores the growing importance of super finishing in various industries, from aerospace to automotive, where surface roughness plays a vital role in the longevity and efficiency of parts.

The significance of reaching a surface roughness of up to Ra 0.1µm cannot be overstated. This level of smoothness is crucial for minimizing friction, reducing wear, and enhancing the overall reliability of mechanical systems. Notably, the process of super finishing involves advanced techniques that refine surfaces beyond traditional methods, ensuring that components meet the stringent requirements of modern engineering. With increasing demand for high-performance materials, understanding the essentials of super finishing has become imperative for engineers and manufacturers alike.

In this article, we will explore the fundamental principles of super finishing, the technologies involved, and practical tips on how to achieve the desired surface roughness, further elaborating on why this process is indispensable for the success of high-precision applications.

The Importance of Super Finishing in Precision Manufacturing

Super finishing is increasingly recognized as a crucial step in the precision manufacturing process, particularly for industries where surface quality can greatly influence performance, such as aerospace, automotive, and medical devices. According to a recent report by the Precision Manufacturing Association, components with a surface roughness of just Ra 0.1µm can lead to a 25% increase in fatigue strength, which is vital for parts subjected to cyclic loading. This underscores the importance of achieving ultra-fine surface finishes to enhance durability and reliability.

Moreover, super finishing techniques, such as super abrasive polishing, have been shown to reduce friction in mechanical systems, which can directly affect energy efficiency. For instance, a study by the International Journal of Mechanical Engineering revealed that a smoother surface achieved through super finishing can decrease wear rates by up to 50% over time. This not only prolongs the life of products but also minimizes the need for frequent replacements, thereby driving down costs for manufacturers and consumers alike.

Understanding Surface Roughness: Defining Ra 0.1µm

Surface roughness plays a critical role in the performance and longevity of machined components. When we refer to Ra 0.1µm, we are discussing an incredibly smooth finish that can significantly reduce friction and wear, thus enhancing the functional life of parts, especially in high-precision applications like aerospace and medical devices.

According to a report by the American Society of Mechanical Engineers (ASME), achieving such a low roughness value can result in a 20% improvement in the efficiency of rotating machinery. This is crucial in industries where precision is non-negotiable, such as semiconductor manufacturing, where surface imperfections can severely impact device performance.

To achieve Ra 0.1µm, super finishing techniques such as lapping, polishing, and honing are applied. These methods focus on removing the microscopic peaks left by previous machining processes, thereby creating an ultra-smooth surface. Industry studies have shown that implementing super finishing can lead to a significant reduction in fatigue failure rates of up to 40% in critical applications.

Tips: When aiming for a surface roughness of Ra 0.1µm, it’s essential to use the correct abrasives that match the material type. Additionally, maintaining a clean and controlled environment during the super finishing process can prevent contaminants from affecting the final surface quality.

Key Techniques and Technologies in Super Finishing

Super finishing is a critical process for achieving exceptionally low surface roughness, particularly in applications requiring precision. Techniques such as honing, lapping, and polishing are commonly employed to enhance surface quality and attain an Ra of up to 0.1µm. These methods allow manufacturers to minimize friction and wear, thereby extending the lifespan of components and improving performance in high-tech industries, including aerospace and automotive.

The Metal Finishers' Association of India (MFAI) will be hosting a three-day conference, bringing together experts and industry leaders to discuss advancements in super finishing technologies. Participants will delve into the latest innovations and methodologies that drive efficiency and precision in surface finishing. Such gatherings provide an invaluable platform for sharing knowledge, exploring new techniques, and fostering collaborations that can enhance the overall quality of metal finishing practices across various sectors.

Applications of Super Finishing in Various Industries

Super finishing, a crucial process in enhancing surface characteristics, finds applications across various industries due to its ability to achieve exceptional surface roughness levels, often as low as Ra 0.1µm. In the automotive industry, for example, super finishing is employed to improve the performance and longevity of engine components.

According to a report by MarketsandMarkets, the automotive super finishing market is projected to reach USD 1.75 billion by 2026, reflecting a CAGR of 7.5%. This growth is driven by the industry's increasing demand for precision components that can withstand extreme conditions while minimizing friction and wear.

In the aerospace sector, super finishing plays a pivotal role in enhancing the performance of turbine engines and other critical components.

A study published in the Journal of Aerospace Engineering indicates that properly finished surfaces can lead to a reduction in fuel consumption by up to 3%, translating into significant cost savings and improved efficiency. Additionally, the medical device industry utilizes super finishing techniques to ensure that surgical instruments meet stringent hygiene and performance standards, thereby minimizing the risk of infection and improving patient outcomes. The emphasis on achieving ultra-smooth surfaces is reflective of the industry's commitment to quality and patient safety.

Benefits of Achieving Ultra-Smooth Surfaces for Performance and Longevity

Achieving ultra-smooth surfaces, particularly with a surface roughness of up to Ra 0.1µm through super finishing, is crucial for enhancing performance and longevity in various applications. Ultra-smooth surfaces reduce friction between moving parts, minimizing wear and tear over time. This reduction not only extends the lifespan of components but also improves their efficiency, leading to better fuel economy in automotive applications or enhanced precision in machinery.

Tips for achieving ultra-smooth surfaces include selecting the right super finishing technique based on the material and intended use. For example, techniques like vibratory finishing or honing can be effective for different materials. Additionally, consistent monitoring of the finishing process helps ensure uniform surface quality, which is essential for high-performance applications.

Another important consideration is lubrication. Implementing appropriate lubrication prevents metal-to-metal contact, further reducing wear and achieving better surface quality. Regular maintenance of machinery that utilizes these ultra-smooth components can also play a significant role in maximizing performance and extending longevity.

Related Posts

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

How to Choose the Right Bevel Gears for Your Precision Engineering Needs

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

-

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future