Top 10 Advantages of the Plastic Injection Moulding Process You Need to Know

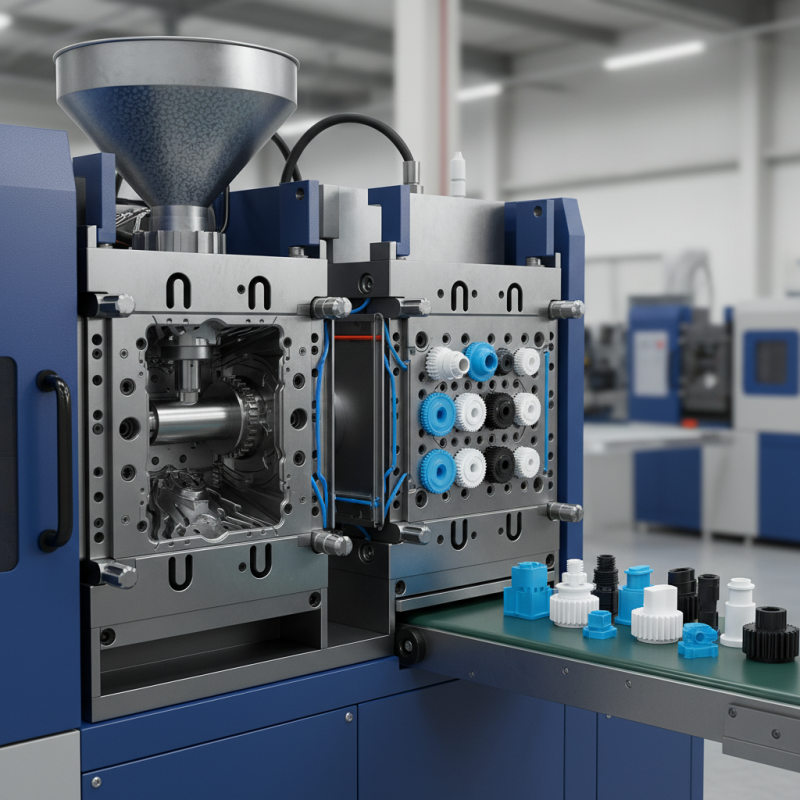

The plastic injection moulding process has revolutionized the manufacturing industry, offering unparalleled efficiency and versatility in producing a wide range of plastic parts and products. As one of the most widely adopted methods of plastic fabrication, it allows manufacturers to create complex shapes with precision and consistency. This process involves injecting molten plastic into a mould, where it cools and solidifies into the desired form. The advantages of this method are numerous, making it a preferred choice for companies looking to optimize their production capabilities.

In this article, we will explore the top ten advantages of the plastic injection moulding process, shedding light on its ability to reduce waste, increase production speed, and enhance product quality. From the significant cost savings associated with high-volume production to the flexibility in material choices, understanding these benefits can help businesses make informed decisions regarding their manufacturing strategies. Whether you are a seasoned industry professional or just beginning to delve into plastic manufacturing, the insights provided will demonstrate why the plastic injection moulding process remains a cornerstone of effective and efficient production.

Overview of Plastic Injection Moulding Process and Its Applications

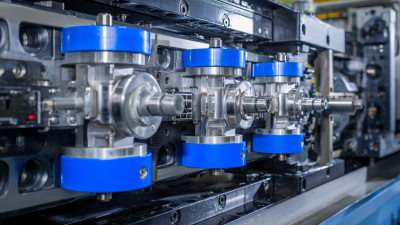

Plastic injection moulding is a highly efficient manufacturing process utilized to produce a wide range of plastic products. This method involves injecting molten plastic into a custom-designed mould, where it cools and solidifies to take the shape of the mould cavity. One of the key advantages of this process is its ability to create complex geometries with high precision, making it ideal for producing intricate components used in various industries, including automotive, electronics, consumer goods, and medical devices.

The applications of plastic injection moulding are vast and continually expanding. It is extensively used in the production of parts like housings, containers, and fittings, thanks to its high-output potential and material versatility. Manufacturers appreciate the process for its ability to streamline production, reduce waste, and ensure uniformity across large batches of products. Additionally, the capability to use multiple materials and colors within a single cycle allows for innovative designs and functionalities, enhancing product appeal and performance. As industries increasingly seek efficient and sustainable manufacturing methods, plastic injection moulding stands out as a leading choice due to these beneficial properties.

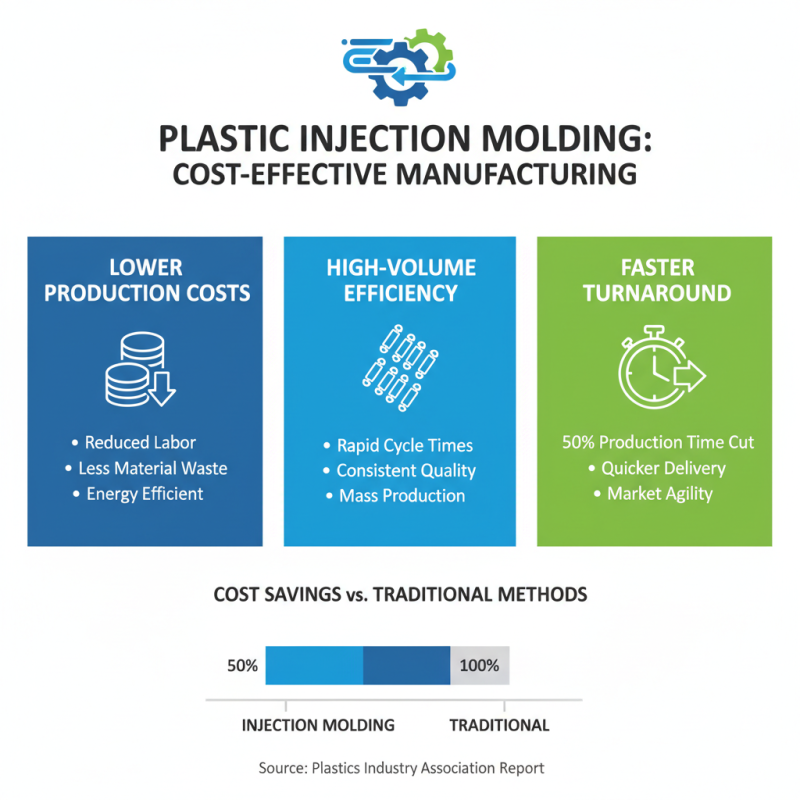

Cost-Effectiveness: How Injection Moulding Reduces Production Expenses

The cost-effectiveness of the plastic injection moulding process is one of its standout advantages, greatly enhancing its appeal to manufacturers across various industries. According to a report by the Plastics Industry Association, the efficiency of injection moulding can significantly lower production costs compared to traditional manufacturing methods. With the capability to produce high volumes of parts in a single cycle, the process reduces both labor and material costs. In fact, industry estimates suggest that injection moulding can cut production time by up to 50%, allowing companies to achieve quicker turnaround times on their manufacturing cycles.

Moreover, the precision and repeatability of injection moulding contribute to its cost advantages. High-quality moulds produce consistent parts with minimal imperfections, which not only decreases waste but also reduces the need for costly post-production processes. A study by the American Society for Quality states that optimally designed injection moulding processes can lead to a reduction of scrap rates by as much as 10%. This efficiency not only drives down costs in terms of materials but also minimizes the environmental impact associated with excess waste. As a result, manufacturers can achieve a competitive edge by harnessing the cost-saving opportunities that injection moulding presents.

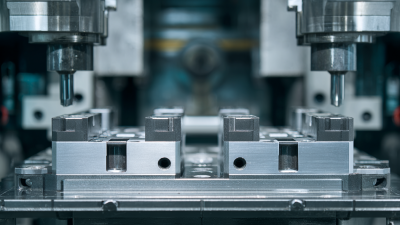

High Precision and Consistency in Product Manufacturing

The plastic injection moulding process stands out for its ability to deliver high precision and consistency in product manufacturing. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to reach $350 billion by 2025, highlighting its widespread adoption in various industries, including automotive, medical, and consumer goods. One of the key reasons for this growth is the method's capability to produce intricate designs with tight tolerances, often achieving dimensional accuracy within ±0.005 inches. This level of precision is crucial for applications where functionality and aesthetics are paramount.

Moreover, the consistency of plastic injection moulding is underscored by its repeatability. With the use of advanced technologies such as computer-aided design (CAD) and automated machinery, manufacturers can consistently reproduce parts within the same specifications, leading to reduced waste and increased efficiency. A study published by the Society of Plastics Engineers (SPE) indicates that manufacturers can expect a production consistency rate exceeding 90% using this technique. This reliability not only minimizes errors but also enhances quality assurance processes, enabling businesses to maintain high standards and meet customer expectations in both small and large production runs.

Versatility of Materials Used in Injection Moulding Techniques

The versatility of materials used in plastic injection moulding is one of the most significant advantages of this manufacturing process. A wide range of thermoplastics, thermosets, and even certain metals can be utilized, making it an ideal choice for diverse applications across multiple industries.

Thermoplastics like ABS, polycarbonate, and polypropylenes offer flexibility and durability, which can be tailored to meet specific requirements. The ability to adapt material properties through additives and blends allows for enhanced performance traits, such as increased heat resistance, improved impact strength, and enhanced aesthetic qualities.

Furthermore, the use of alternative materials such as bio-based plastics and high-performance polymers opens new avenues in sustainable manufacturing and specialized applications. This adaptability not only facilitates the production of complex geometries and intricate designs but also aligns with modern demands for eco-friendly solutions.

The variety of materials combined with advanced injection moulding techniques ensures that manufacturers can fulfill unique design specifications while maintaining consistency and quality in mass production. This capability reinforces plastic injection moulding's status as a leading manufacturing method, capable of meeting diverse consumer needs and evolving industry standards.

Environmental Benefits and Sustainability in Plastic Injection Moulding

The plastic injection moulding process not only offers numerous advantages in manufacturing efficiency but also contributes significantly to environmental sustainability. This method allows for the precise shaping of plastic materials, reducing waste to a minimum. By using advanced techniques like recycling and reprocessing, manufacturers can reuse scrap material, thus minimizing the environmental footprint associated with production. Furthermore, with properly managed operations, this process consumes less energy compared to traditional plastic manufacturing methods.

When considering plastic injection moulding, one tip to keep in mind is to choose biodegradable or recycled materials whenever possible. This not only enhances the sustainability of the final product but also improves the overall lifecycle impact of the items produced. Additionally, optimizing mold designs for energy efficiency, such as using multi-cavity molds, can lead to reduced energy consumption and lower operational costs.

Moreover, implementing efficient production practices can further promote sustainability. Regularly assessing production lines for potential upgrades or retrofits that enhance energy efficiency can greatly reduce emissions. Embracing technology, such as automation and smart manufacturing solutions, can streamline operations and contribute to a cleaner environment, making the plastic injection moulding process a more attractive choice for eco-conscious businesses.

Related Posts

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation

-

How to Achieve Superior Results with Super Finishing Techniques