Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners

The plastic injection moulding process is a crucial manufacturing technique widely employed in various industries, significantly contributing to the production of plastic parts and products. According to a recent report by MarketsandMarkets, the global market for injection moulding is projected to reach USD 325.2 billion by 2027, driven by the increasing demand for lightweight and durable components across sectors such as automotive, electronics, and consumer goods. This comprehensive guide aims to equip beginners with a solid understanding of the plastic injection moulding process, highlighting key methodologies, essential equipment, and various tips for optimizing production efficiency. By delving into the intricacies of this process, readers will gain insight into how mastering these techniques can enhance product quality and reduce manufacturing costs, thereby positioning themselves for success in the competitive landscape of modern manufacturing.

Key Components of the Plastic Injection Moulding Process Explained

The plastic injection moulding process is a crucial method used in manufacturing a variety of plastic products. Understanding its key components is essential for beginners looking to enter this industry. At the heart of the process are several vital elements including the injection unit, clamping unit, and mold. The injection unit melts the plastic pellets and injects the molten material into the mold, while the clamping unit securely holds the mold in place during the injection. Proper functioning of these components ensures precision and efficiency in producing high-quality plastic parts.

As the global micro injection molding machine market is projected to grow from $551.3 million in 2025 to $759.2 million by 2032, it highlights the increasing demand for advanced manufacturing techniques in the plastics industry. Companies are seeking ways to enhance production capabilities while maintaining accuracy in small, intricate designs.

Tips: When selecting a moulding machine, consider the size and complexity of the parts you intend to produce. Additionally, ensuring consistent temperature control during the melting process can significantly affect the quality and durability of the finished product. Always keep up with industry trends to remain competitive and informed about the latest technologies and materials available.

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners - Key Components of the Plastic Injection Moulding Process Explained

| Component | Description | Material Used | Function |

|---|---|---|---|

| Injection Machine | A machine that injects molten plastic into a mould. | Steel, Aluminum | Melts and injects plastic into the mould. |

| Mould | The cavity that shapes the plastic as it cools. | Steel, Aluminum | Creates the desired shape of the final product. |

| Hopper | The chamber that feeds plastic pellets into the machine. | Plastic | Stores and supplies raw material for injection. |

| Nozzle | The part through which molten plastic is injected into the mould. | Steel | Delivers molten plastic to the mould. |

| Cooling System | Circulates coolant to cool the molten plastic in the mould. | Water, Oil | Solidifies the plastic for easy ejection from the mould. |

| Ejection System | Mechanism used to remove finished products from the mould. | Steel | Ensures easy removal of the product post-cooling. |

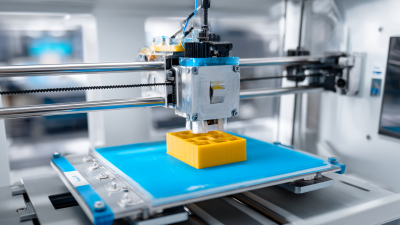

Step-by-Step Breakdown of the Plastic Injection Moulding Workflow

The plastic injection moulding process is a pivotal manufacturing method used across various industries, renowned for its efficiency and precision. This workflow typically begins with the creation of a mould, which is custom-designed to shape the plastic product. According to the American Society of Plastics Engineers, the global plastic moulding industry is projected to grow significantly, expected to reach a market value of approximately $300 billion by 2025. This growing demand underlines the importance of understanding the intricate steps involved in the injection moulding process.

Once the mould is ready, the process moves into the actual injection phase. Plastic pellets are fed into a heated barrel where they are melted and then forcefully injected into the mould under high pressure. This phase is crucial, as the quality of the final product heavily relies on the temperature and pressure applied during injection. Data from the Plastics Industry Association illustrates that optimally controlled injection parameters can enhance product strength and reduce cycle times. After cooling and solidification, the mould opens to release the finished piece, completing the cycle. Understanding these steps is essential for beginners aiming to implement efficient practices in plastic production.

Essential Equipment Required for Effective Injection Moulding

When delving into the plastic injection moulding process, it's crucial to understand the essential equipment required for effective production. At the core of this process are injection moulding machines, which can be classified into hydraulic, electric, and hybrid types. According to the latest industry report by MarketsandMarkets, the global injection moulding machine market is projected to reach around $17.6 billion by 2026, reflecting the rising demand for efficient manufacturing solutions. Each type of machine has its specific advantages; for instance, electric machines are known for their precision and energy efficiency, while hydraulic machines are favored for their substantial clamping force.

When delving into the plastic injection moulding process, it's crucial to understand the essential equipment required for effective production. At the core of this process are injection moulding machines, which can be classified into hydraulic, electric, and hybrid types. According to the latest industry report by MarketsandMarkets, the global injection moulding machine market is projected to reach around $17.6 billion by 2026, reflecting the rising demand for efficient manufacturing solutions. Each type of machine has its specific advantages; for instance, electric machines are known for their precision and energy efficiency, while hydraulic machines are favored for their substantial clamping force.

In addition to injection moulding machines, other critical equipment includes moulds, temperature control units, and conveyors. Moulds are custom-made and can significantly impact the end product's quality and production speed. It's estimated that the quality of the mould can account for up to 60% of the production cycle efficiency. Temperature control units are essential for managing the cooling process, ensuring that the material solidifies correctly, which can optimize production times and reduce waste.

Tips: Always invest in high-quality moulds that suit your specific product requirements to enhance durability and reduce maintenance costs. Regular maintenance of your injection moulding machine will also lead to consistent output quality, minimizing downtime and maximizing profitability. Lastly, implement regular training for your operators to keep them updated on the best practices for operating machinery efficiently.

Common Challenges in Plastic Injection Moulding and Their Solutions

Plastic injection moulding is a widely used manufacturing process, but it comes with its own set of challenges. One common issue is air trapping, which can lead to voids in the finished product. This occurs when air is unable to escape from the mould during the injection, resulting in poor part quality. Solutions include optimizing the mould design to include venting channels and adjusting the injection speed to allow air to escape more effectively.

Another significant challenge in plastic injection moulding is the variability in materials. Different batches of plastic can exhibit varying properties, which can impact the consistency of the final product. To address this, manufacturers often conduct thorough quality control checks on incoming materials and may opt for a more standardized material supplier to ensure uniformity. Regular maintenance of injection moulding machines is also crucial to adjust for any wear and tear that could affect production quality. By implementing these strategies, manufacturers can enhance the efficiency and reliability of the injection moulding process.

Tips for Beginners to Optimize Injection Moulding Efficiency

The injection moulding process is a highly efficient manufacturing technique that transforms raw plastic materials into precise shapes. For beginners looking to enhance their injection moulding efficiency, there are several key strategies to consider. First, ensuring that the material is perfectly prepared before the injection process can significantly reduce defects and improve the quality of the final product.

One innovative approach involves leveraging advanced techniques like active transfer learning. This method is part of a novel framework that optimizes injection-moulded components such as magnets. By integrating such technologies, beginners can better predict outcomes and fine-tune the parameters of their processes for enhanced performance.

Additionally, incorporating hybrid inserts through additive manufacturing has proven beneficial in mould production. These inserts not only streamline the injection process but also provide durability and precision in moulding. Implementing these tips can lead to a more efficient workflow and higher quality products, making them indispensable for those new to the field.

Related Posts

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025